A gantry crane is an overhead crane that has two more beams that are supported by legs. These cranes move on wheels, tracks, or rails. Gantry cranes are used widely in workshops, warehouses, shipyards, and railroads. Gantry cranes are designed in a way to carry small loads as well as heavy-duty ones. Read More…

We are Givens Lifting Systems, Inc., a leading company specializing in providing high-quality lifting solutions, with a primary focus on cranes. With our extensive expertise and commitment to innovation, we have established ourselves as a trusted partner for various industries worldwide.

PWI cranes are ready to help with any of your material handling needs. Our overhead bridge cranes are typically for heavy-duty material handling needs. Workstation cranes are lightweight and can be installed in any workspace. Jib cranes provide an excellent way to transfer material from on station to another. Gantry cranes work great for moving overhead cranes to different areas. Our team is...

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

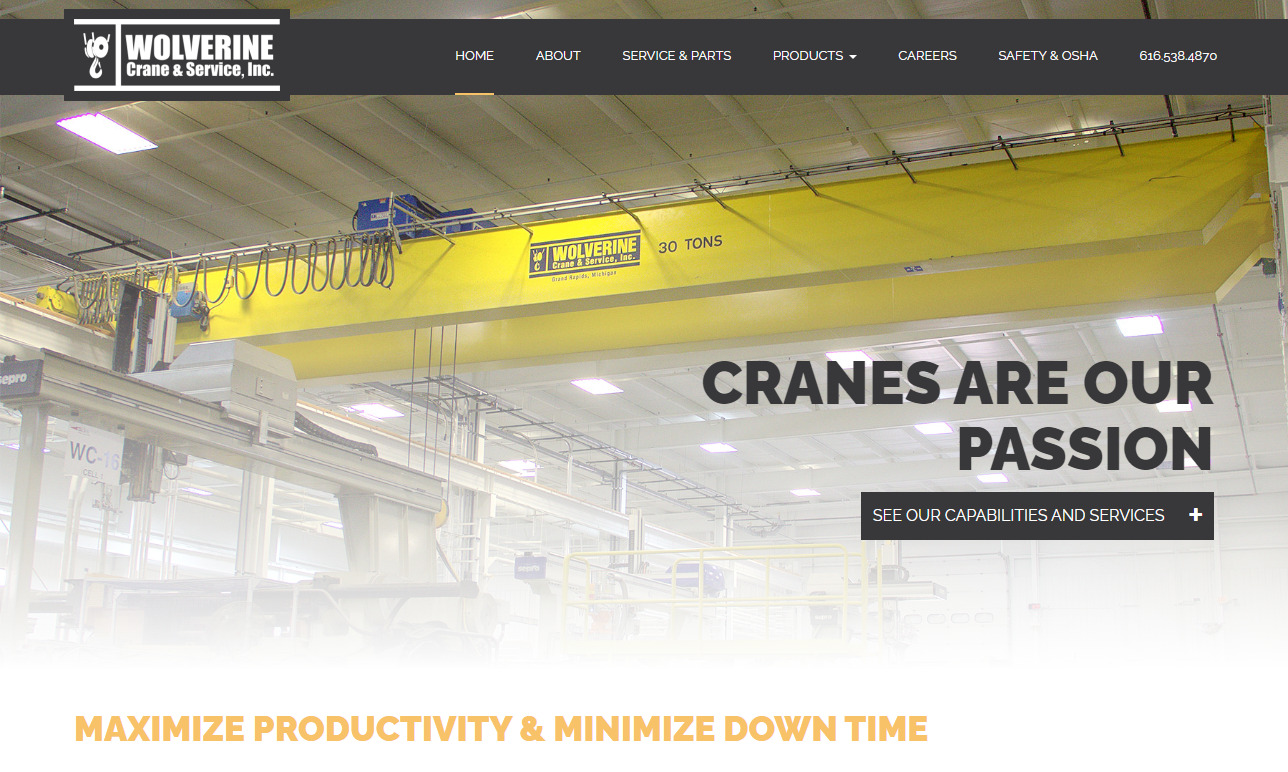

As a Factory Authorized R&M Master Distributor and Crane Builder, Wolverine provides its customers with the finest production built crane components available. Some of the products we provide include gantry cranes, overhead cranes, chain and wire rope hoists and much more. Regardless of your needs, we design, build, and install custom systems to fit any process or application.

At TC/American Crane Company, we design, manufacture, and support custom crane systems that deliver reliability, precision, and long-term performance across a wide range of industrial environments. As pioneers in the field, we bring decades of engineering expertise to every overhead lifting solution we create, integrating innovative track systems, patented components, and tailored configurations...

Our hundreds of pre-engineered cranes can be cost-effectively customized by our certified engineers for unusual applications, including low ceilings, obstacles, and atypical capacities. All Spanco cranes come with the best warranties in the industry.

More Gantry Crane Manufacturers

Gantry Cranes: Types, Components, Applications & Selection Guide

Gantry cranes are essential industrial lifting solutions widely used for handling heavy materials across various industries. Available in both single girder gantry cranes and double girder gantry cranes configurations, these lifting machines are engineered to deliver optimal performance, safety, and efficiency in material handling operations.

Single girder gantry cranes are designed to carry lighter loads, making them ideal for workshops, small warehouses, and maintenance tasks. Double girder gantry cranes, on the other hand, are built for heavy-duty applications, providing greater lifting capacity, enhanced stability, and superior span. Understanding the differences between these types is crucial for selecting the right crane for your specific application.

What Are Gantry Cranes?

A gantry crane is a type of overhead crane system featuring a bridge supported by legs that move on wheels or rails, as opposed to being suspended from a building structure. Gantry cranes can lift loads ranging from a few hundred pounds to several hundred tons and are available in a variety of shapes, such as the classic “A” frame, as well as “L” and “U” shaped leg designs. The “A” frame is the most common due to its stability and versatility.

All gantry cranes, whether single or double girder, are designed for both light-duty and heavy-duty lifting. The higher the crane’s capacity, the more robust its construction and performance. While double girder cranes generally come at a higher cost, they offer distinct advantages in terms of load size, span, and safety for demanding applications.

Height is another customizable feature, with gantry cranes available in both fixed and adjustable height models to suit different working environments and object sizes.

Construction of Gantry Cranes

Understanding the construction of gantry cranes is key to evaluating their durability, functionality, and suitability for your project. Each gantry crane, regardless of size or capacity, is comprised of three main component categories:

- Mechanical Components – Includes motors, gearboxes, brakes, and moving mechanisms responsible for lifting and travel functions.

- Structural Components – Encompasses the main girder(s), supporting legs, end carriages, and base structure, engineered to withstand operational loads and environmental stresses.

- Electrical Components – Covers the power supply system, control panels, wiring, and safety interlocks facilitating efficient and secure crane operation.

Girders or beams are integral to all gantry crane types, positioned above ground and parallel to the working surface. The design and construction of the frame, legs, and girders differentiate gantry cranes from other overhead lifting equipment like bridge cranes. The legs can feature straight beams, truss structures, or the common A-frame style, providing a range of options for different workspace and load requirements.

Key Components of Gantry Cranes

To maximize performance and ensure safety, it is critical to understand the function and features of each major gantry crane component:

1. Frame

The frame is the fundamental structure, consisting of one or two main girders and supporting legs. The number, length, and size of beams are determined by the weight and dimensions of the loads to be lifted. In semi-gantry cranes, only one leg is present, with the opposite side supported by a building structure or wall. The design often incorporates a rigid leg for stability and a flexible leg to minimize dead weight and adapt to floor irregularities.

2. Trolley

The trolley houses the hoist and moves horizontally along the crane’s girder. Trolley configurations include low headroom, normal headroom, and double girder types. Some advanced trolleys are equipped with adjustable space washers, allowing operators to tailor the trolley width to specific application needs. For safety and smooth operation, wheel bumpers and side guide rollers are often installed to prevent collisions and lateral movement.

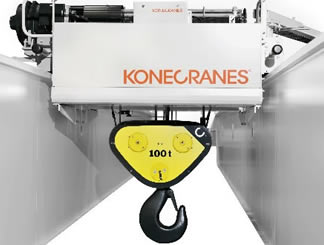

3. Hoist

The hoist mechanism is responsible for the vertical lifting and lowering of loads. Gantry cranes may use chain hoists for lighter applications (up to five tons) and wire rope hoists for heavier loads. High-capacity electric wire rope hoists are standard for double girder gantry cranes used in shipyards, steel mills, and construction sites. Choosing the right hoist type impacts lifting speed, operational efficiency, and safety.

4. Power Supply

Power is delivered to the trolley and hoist via a festoon system—a series of cable carriers—or conductor bars. The main panel supplies direct AC or induction AC power, ensuring reliable and consistent performance. For outdoor or mobile gantry cranes, power options may include battery packs or diesel generators for off-grid operations.

5. Controls

Modern gantry cranes offer advanced control options, including push-button pendants, radio remote controls, and even smart automation systems with programmable logic controllers (PLC). These controls enable precise positioning, speed regulation, and enhanced safety through features like overload protection and emergency stops.

Types of Gantry Cranes

There are several types of gantry cranes, each engineered for specific industrial applications and facility layouts. Understanding the differences will help you choose the right gantry crane system for your material handling requirements. Explore the following categories:

Full Gantry Crane

The classic full gantry crane features a bridge, two supporting legs, and a hoist. It travels on wheels, rails, or a track. Full gantry cranes are available in stationary and portable models, offering flexibility for both indoor and outdoor use. Their robust design makes them ideal for shipyards, container terminals, and heavy manufacturing.

Semi-Gantry Crane

Semi-gantry cranes combine the benefits of overhead and gantry cranes by implementing one supporting leg and a wall-mounted I-beam on the opposite side. These cranes are commonly used in workshops, factories, and storage yards with space limitations. Semi-gantry cranes can be installed under existing overhead cranes to maximize material handling efficiency within a single workspace.

Portable Gantry Crane

Portable gantry cranes are lightweight, mobile cranes mounted on casters or rubber wheels. With lifting capacities from 0.5 tons to 5 tons, these cranes can be quickly relocated within a facility for maintenance, assembly, or warehouse operations. Their mobility and ease of setup make them popular for contractors, repair shops, and aerospace applications.

Adjustable Gantry Crane

Adjustable gantry cranes feature telescoping legs or crossbeams, allowing users to modify the height and span to accommodate different load sizes or workspace constraints. Available in both portable and fixed models, these versatile cranes are suitable for environments where flexibility and adaptability are essential.

Single Girder Gantry Crane

Single girder gantry cranes utilize one bridge beam with a hoist trolley operating on the lower flange. They are cost-effective, simple to install, and require less maintenance, making them ideal for facilities with moderate lifting demands. Typical applications include fabrication shops, assembly lines, and indoor warehouses.

Double Girder Gantry Crane

Double girder gantry cranes consist of two parallel beams forming the bridge, supporting a trolley that runs on top or beneath the girders. These cranes are engineered for heavy-duty lifting, large spans, and high-frequency usage. With strong load-bearing capacity and enhanced stability, double girder gantry cranes are preferred for steel mills, shipbuilding docks, and container handling terminals.

Truss Gantry Crane

Truss gantry cranes incorporate a latticed, lightweight structure that offers excellent load distribution and resistance to wind. Their design makes them suitable for outdoor environments, such as construction sites and equipment yards, where durability and reduced weight are priorities.

Box Gantry Crane

Box gantry cranes are constructed with enclosed box-shaped girders, providing maximum rigidity and strength. These are used in situations where overhead cranes are impractical, such as open yards or sites with space constraints. Double-box designs are engineered for extremely heavy loads and demanding applications.

L-Shaped Gantry Crane

L-shaped gantry cranes feature uniquely angled legs with attached hooks, designed specifically for loading and unloading operations at seaports, logistics terminals, and large warehouses. Their shape facilitates the handling of oversized or awkwardly shaped cargo.

U-Shaped Gantry Crane

U-shaped gantry cranes offer increased space between the legs, accommodating wider loads and large equipment. They are particularly useful for heavy-duty applications in shipyards, power plants, and industrial assembly areas.

Workstation Gantry Crane

Workstation gantry cranes are compact, ergonomic lifting systems designed for repetitive, light-duty tasks in manufacturing, packaging, and laboratory environments. They feature a movable bridge running across parallel runways and can be equipped with hoists, manipulators, or intelligent lifting devices to streamline workflow and reduce operator fatigue.

Common Applications and Use Cases for Gantry Cranes

Gantry cranes are indispensable across a wide spectrum of industries due to their versatility, mobility, and high lifting capacity. Major application areas include:

- Manufacturing and Assembly Plants: Moving raw materials, components, and finished products efficiently throughout the production line.

- Warehouses and Distribution Centers: Streamlining storage, retrieval, and order fulfillment processes.

- Shipyards and Maritime Facilities: Loading and unloading heavy containers, ship components, and equipment with precision.

- Construction Sites: Lifting steel beams, concrete sections, and large machinery for building infrastructure.

- Railroads and Transport Hubs: Handling railcars, maintenance equipment, and track components safely and quickly.

- Automotive Industry: Supporting vehicle assembly, part transfer, and maintenance operations.

- Aerospace and Defense: Safely moving aircraft parts, engines, and sensitive equipment.

- Power Plants and Utilities: Installing turbines, transformers, and large-scale electrical components.

Are you wondering if a gantry crane is the right solution for your workspace? Consider your lifting requirements, workspace layout, and future scalability needs when evaluating different gantry crane options.

Benefits of Using Gantry Cranes

Why choose a gantry crane over other material handling systems? Here are the key advantages:

- Versatility: Suitable for both indoor and outdoor use, with a wide range of configurations and capacities.

- Mobility: Portable gantry cranes offer easy relocation to different work areas, reducing bottlenecks and downtime.

- Cost-Effectiveness: Installation and maintenance costs are often lower than permanent overhead crane structures.

- Customization: Adjustable height, span, and girder options allow for tailored solutions to meet unique operational needs.

- Efficiency: Reduces manual labor, speeds up workflow, and improves workplace safety.

- Robust Construction: Engineered for longevity and consistent performance, even in harsh environments.

- Enhanced Safety: Modern gantry cranes incorporate advanced safety features, overload protection, and fail-safes.

Looking to optimize your facility’s material handling processes? Explore how gantry cranes can streamline operations, improve safety, and boost productivity in your industry.

How to Select the Right Gantry Crane for Your Application

Choosing the best gantry crane system requires a clear understanding of your operational requirements, budget, and long-term business goals. Consider the following factors when selecting a gantry crane:

- Lifting Capacity: Assess the maximum weight your crane will need to lift. Consider future expansion and potential increases in load size.

- Span and Height: Measure the distance between the legs (span) and required under-hook height to ensure compatibility with your workspace and materials.

- Duty Cycle and Frequency: Determine how frequently the crane will be used—light, moderate, or heavy-duty cycles—and select a model rated for your operational demands.

- Mobility and Flexibility: Decide between stationary or portable gantry cranes based on your workflow and facility layout.

- Indoor vs. Outdoor Use: Choose weather-resistant materials and corrosion protection if your crane will be exposed to the elements.

- Power and Controls: Evaluate available power sources (AC, DC, generator) and control systems (pendant, remote, automation).

- Safety Features: Ensure the crane includes overload protection, emergency stops, and compliance with OSHA or relevant safety standards.

- Installation and Maintenance: Factor in installation requirements, ongoing maintenance needs, and support services offered by the supplier.

Not sure which gantry crane is right for your business? Contact experienced gantry crane suppliers and request a consultation to discuss your specific needs and receive tailored recommendations.

Choosing the Correct Gantry Crane Supplier

To achieve the best value and performance when purchasing gantry cranes, it’s crucial to partner with a reputable supplier or manufacturer. Here’s how to make an informed decision:

- Compare Multiple Suppliers: Use our curated list of gantry crane suppliers to compare at least four manufacturers. Assess their experience, capabilities, and product offerings.

- Review Business Profiles: Each supplier profile highlights areas of specialization and technical expertise. Check for certifications, project portfolios, and customer testimonials.

- Request Detailed Quotes: Use the integrated contact forms to request product catalogs, technical specifications, and custom pricing for your application.

- Evaluate Support Services: Consider after-sales support, installation services, training, and maintenance packages offered.

- Use Our Website Previewer: Preview each supplier’s website to gain insight into their product range, innovation, and customer service philosophy.

- Leverage Our RFQ Tool: Submit a single RFQ form to contact multiple gantry crane businesses, streamlining your procurement process.

Looking for expert guidance? Read our buyer’s guide or reach out to leading gantry crane manufacturers for personalized advice on selecting, installing, and maintaining your new crane system.

Frequently Asked Questions About Gantry Cranes

What are the main differences between gantry cranes and bridge cranes?

While both are overhead lifting systems, gantry cranes use free-standing legs that travel on rails or wheels, making them portable and suitable for outdoor or temporary applications. Bridge cranes are permanently mounted to building columns and are typically used indoors for long-term operations. Learn more about bridge cranes.

Can gantry cranes be customized for unique applications?

Yes. Leading manufacturers offer custom-engineered gantry cranes tailored to specific height, span, capacity, and control requirements. Custom options may include explosion-proof electricals, corrosion-resistant coatings, and advanced automation.

What safety standards apply to gantry cranes?

Gantry cranes should comply with industry standards such as OSHA, ANSI, and CMAA. Features like overload protection, emergency stop systems, and regular inspections are essential for safe operation.

How do I maintain my gantry crane to ensure longevity?

Regular maintenance includes inspecting structural components, lubricating moving parts, checking electrical systems, and testing safety devices. Manufacturers typically provide maintenance schedules and support services to maximize crane lifespan.

What industries benefit most from gantry cranes?

Industries such as manufacturing, shipbuilding, logistics, transportation, construction, and utilities rely on gantry cranes for efficient material handling, heavy lifting, and improved workplace safety.

Start Your Search for the Ideal Gantry Crane

Ready to improve your facility’s productivity with a reliable gantry crane system? Explore our comprehensive supplier directory to compare models, request quotes, and connect with top manufacturers. Whether you need a portable gantry crane for your workshop or a double girder gantry crane for heavy industrial use, our resources make your buying process simple and efficient.

Still have questions? Contact our industry experts or browse our in-depth guides on material handling equipment to make a confident, informed purchase decision.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches