Overhead cranes are impressively diverse mechanisms used to lift, lower, and generally transport loads of various shapes, sizes, and weights. Also, commonly known as lifting cranes or hoist cranes, most overhead cranes can crane and hoist and loads that weigh up to approximately 1,000 tons. Read More…

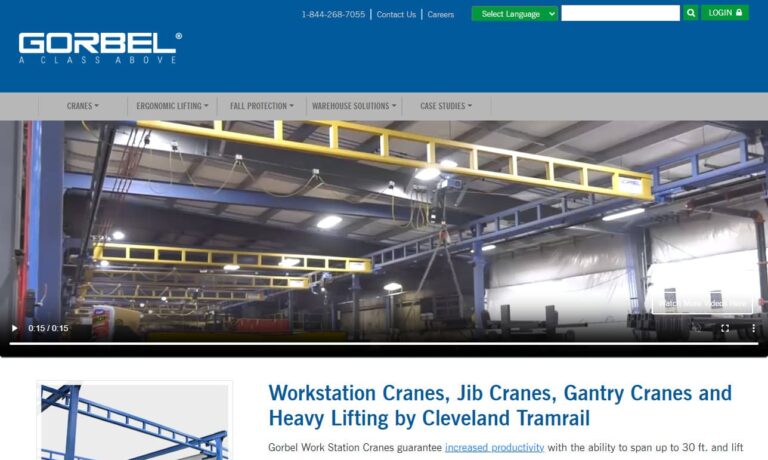

Gorbel®, Inc. is an innovator and leader in producing bridge cranes for the industry. Gorbel® provides a wide variety of overhead handling solutions that handle loads from fifty pounds up to forty tons. Contact us today and we will work with you to find the best product for your unique application. Call or visit our website for additional information.

PWI cranes are ready to help with any of your material handling needs. Our overhead bridge cranes are typically for heavy-duty material handling needs. Workstation cranes are lightweight and can be installed in any workspace. Jib cranes provide an excellent way to transfer material from on station to another. Gantry cranes work great for moving overhead cranes to different areas. Our team is...

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

We are Givens Lifting Systems, Inc., a leading company specializing in providing high-quality lifting solutions, with a primary focus on cranes. With our extensive expertise and commitment to innovation, we have established ourselves as a trusted partner for various industries worldwide.

At Simmers, we can take a new crane project from start to a turnkey finish. We will supply all equipment through our network of vendors and fabricate the crane at one of our facilities. We also offer field installation after the crane is built. Our highly qualified and trained staff will design a crane that meets your needs and CMAA design standards. For more information on how Simmers crane can...

Bridge Crane is a problem-solving organization that specializes in customized design, manufacturing, installation, and servicing of overhead and work station crane systems. We are dedicated to safety, efficiency, and practical solutions to meet our customer’s material handling needs.

More Crane Manufacturers

Overhead cranes, also known as lifting or hoist cranes, are versatile mechanisms designed to lift, lower, and transport loads of various shapes, sizes, and weights, with capacities up to approximately 1,000 tons. Powered by hydraulics, internal combustion, or electric batteries, these cranes are essential in commercial and industrial settings. They are commonly used in paper mills, automobile manufacturing facilities, refineries, and other industries. Typical applications include the construction and maintenance of paper machines and heavy press roles, raw material handling, hot metal storage, and steel refinement.

History of Cranes

The precursor to the modernindustrial crane originated in 6th century BC Greece. During this period, the Archaic Greeks began using the winch and pulley hoist instead of ramps and cranes in construction. They later developed the compound pulley. Following the Roman period, advancements in winch and pulley systems led to the creation of the treadmill crane, which remained prevalent for over a millennium until the Roman Empire’s decline. Rediscovered during the Middle Ages, the treadmill crane saw renewed use.

The Industrial Revolution marked a significant evolution in crane technology. In 1838, William Armstrong invented the first hydraulic water-powered crane. Concurrently, German manufacturers began mass-producing overhead cranes. Between the late 1800s and early 1900s, innovations in powering machinery emerged, including electric motors, internal combustion engines, and steam engines. The first steam-powered overhead crane was installed in 1860 by John Ramsbottom at Crewe Railway’s workshop. In 1876, Sampson Moore introduced the first electric overhead crane, with mass production starting around 1910. The Royal Arsenal in Woolwich, London, utilized this crane for over a century before it was retired and relocated to a museum in Birmingham, Alabama, in 1980. The tower crane was first introduced in 1908.

The mid-20th century saw the development of more versatile cranes. Post-World War II, Hans Liebherr and his team in Germany pioneered the first mobile cranes. Today, companies produce overhead cranes that are stronger and more adaptable than ever before.

How Cranes Work

Regardless of the type, overhead cranes operate using pulleys and cables to hoist, lift, lower, carry, and position loads. These components are attached to one or two overhead steel beams (girders), which provide structural support. Various overhead cranes incorporate additional mechanisms such as counterweights, hydraulic cylinders, chain hoists, levers, and pivoting arms to enhance their functionality.

Types of Cranes

Overhead cranes are available in various configurations, including stacker cranes,jib cranes, gantry cranes, and bridge cranes.

Stacker cranes move vertically or horizontally on tracks to reach and transport items, often serving as forklift alternatives in inaccessible warehouse areas and CNC-operated systems.

Jib cranes are smaller, workstation cranes suitable for work on military vehicles and in industrial plants. Their movable hoist, supported by a vertical jib or wall fixture, extends on a pivot, allowing horizontal movement up to 180 degrees. Unlike semi-gantries with fixed arms, jib cranes do not use runways and can be stand-alone or wall-mounted, offering various capacities, spans, and heights. They are space-saving, economical, and can rotate 180-360°, making them ideal for small spaces.

Gantry cranes are constructed on gantries, which consist of two movable support structures that straddle a workspace or object. In some cases, a crane is supported by only one gantry and a counterbalance, referred to as a semi-gantry, half gantry, or cantilever gantry crane. The main types of crane gantries include ship-to-shore, full gantry, portable gantry, rubber tyre gantry, and workstation gantry cranes, the latter being suited for handling smaller items in compact environments.

Unlike bridge cranes, gantry cranes use legs to support trolleys and hoists. These legs move along fixed rails that are either embedded in or laid on the ground. Gantry cranes are ideal for locations where overhead runways are unnecessary, particularly in outdoor settings such as shipyards and railyards. They are typically employed for large-scale applications including bridge construction, monument construction, ship cargo loading and unloading, metalworking, and the movement of ships and vehicles.

Bridge cranes, also known as track cranes, share similarities with gantry cranes as both use structural support beams and a trolley to straddle their load. The key distinction is that while gantry cranes are typically fully mobile, bridge cranes have fixed structures with only a movable hoist. Bridge cranes feature two overhead runways integrated into the building’s support system and come in two configurations: single girder and double girder. They facilitate vertical movement along the runway.

There are two main types of bridge cranes based on capacity and environment: process cranes and modular cranes. Process cranes are heavy-duty, top-running, double girder configurations designed for specific, high-capacity lifts (classes D, E, and F). They are used in demanding environments such as automotive assembly plants, steel mills, container yards, and lumber mills. Modular cranes are more economical, suitable for class C applications, and with some engineering, for class D. They are typically found in smaller manufacturing facilities, mills, and machine shops. These cranes operate using overhead rails and are primarily used for manufacturing or maintenance within a single facility. Bridge cranes are valued for creating an ergonomic, organized workspace and for their safety and ease of handling.

Tower cranes are specialized cranes engineered for demolition and construction projects. Key features include a tall mast, a securely bolted base, and a slewing unit that allows for rotational movement. Mobile cranes refer to any crane that is portable. These cranes are typically mounted on a land vehicle, ship, or airplane for ease of transportation. Rubber-tyred gantry cranes are a type of mobile gantry crane used specifically for stacking or grounding containers.

Overhead shop cranes are vital in auto shops, allowing workers to access and work on the underside of vehicles. These cranes are specialized equipment designed to lift and move heavy objects with precision. They come in various configurations tailored to specific needs and applications, with parts that can be engineered or swapped to enhance efficiency, capacity, and performance.

In addition to auto shops, overhead cranes are indispensable in various industries. They facilitate the loading and unloading of materials from trucks, streamline the movement of materials within a facility, and assist in flipping and pulling dies from stamping machines. Manufacturing facilities rely on them for feeding raw materials into machines and ensuring controlled material movement. Furthermore, overhead cranes play a crucial role in transporting containers at shipyards and railyards.

Similar to overhead cranes, electric wire rope hoists are also used as lifting mechanisms, providing additional options for precise and efficient material handling.

Electric wire rope hoists are designed to efficiently transport exceptionally heavy loads. These overhead electric hoists can be mounted directly to the ceiling or a single girder. Powered by an electric motor, they utilize wire rope, composed of wire strands encasing a rubber core, to perform the hoisting operations.

Workstation cranes are specifically engineered for ergonomic lifting and moving of loads. Designed for lighter-duty tasks, they perform well in smaller spaces. These cranes can be either free-standing or ceiling-hung and are available in both under-running and over-running configurations. Their versatility allows for customization to meet specific requirements.

Monorail cranes utilize a trolley to move hoists along a single track, commonly seen in production or assembly lines. Typically, materials are transported back and forth in a straight line. However, the system can include switches, branches, and elevation changes to create curved paths. These cranes are specifically designed for lifting operations.

Crane Equipment Components

Typical crane components include the bridge, hoist, crane attachment, and trolley. The bridge, an overhanging arm, provides the majority of the crane’s lifting power. The crane bridge is a vital structural element that connects the runways and facilitates the forward and backward movement of the hoist via the trolley. The bridge, which spans the width of the building, is a load-bearing beam made of rolled steel, and it can consist of one or two beams, known as single girder and double girder, respectively. These girders may also be fabricated by welding the beams into steel box designs.

The hoist, which raises and lowers loads, connects to the bridge on one end and to the crane attachment on the other. This attachment can be a variety of tools, such as a hook, fork, auger, or grapple, and is connected to the hoist using wire rope or nylon cables. The crane hoist is a crucial component responsible for raising, lowering, holding, and lifting loads using either a chain or rope. This operation can be powered manually, electrically, or through air pressure. The load is securely supported by the hook, which is attached to the hoist.

The trolley, an electrically or mechanically powered mechanism, moves the hoist along the bridge and may also have additional attachments, like the boom, which is connected horizontally to assist in hoisting and lowering. The trolley component holds the hoist and enables horizontal movement, allowing the precise positioning of the hoist and hook before picking up a load. Trolleys are classified into two categories: under running and top running.

The crane runway is an integral part of the building structure, consisting of beams on which the crane moves. Rails are installed on the runways to facilitate the bridge’s back-and-forth movement. End trucks, located on either side of the bridge, utilize wheels to move the bridge up and down. The wheel configuration varies (2, 4, or 8 wheels) depending on the crane’s movement requirements.

Bumpers are designed to absorb the energy of the crane, reducing impact by providing controlled rest and minimizing forces when the crane reaches its endpoint. Controls for the crane are typically located on a panel, from which all crane movements are managed.

Benefits of Cranes

Overhead cranes provide numerous advantages to users, including efficiency, safety, versatility, ease of use, and low labor and maintenance costs.

Efficiency: Overhead cranes, with their minimal moving parts, can transport materials and products that are significantly heavier than those handled by more complex machinery, such as forklifts and lifting excavators. They operate with lower energy consumption and fuel usage, enhancing work efficiency by 2-3 times compared to manual labor.

Safety

Overhead cranes, operated via wireless controls, enhance operator safety significantly. When used correctly by skilled workers, they minimize on-site accidents. Operators can load and unload from a safe distance, ensuring safety during the handling of hazardous materials or machinery. These cranes are a vital safety feature in warehouses and manufacturing facilities.

Versatility

Overhead cranes offer significant versatility. Equipped with additional tools, a single crane can perform various tasks. They can be modified on-site to handle new or changing applications and are suitable for both indoor and outdoor use. Additionally, their adaptability allows them to accommodate a wide range of lifting applications efficiently.

Overhead cranes are notably user-friendly compared to other lifting equipment. They eliminate the need for manual lifting, as the bridge and attachments handle the majority of the workload. Additionally, while training for similar lifting equipment can take several weeks, mastering the use of overhead cranes typically requires only a few days.

Costs

Overhead cranes significantly reduce labor costs compared to similar equipment. A single operator can manage the crane loads without the need for extensive maneuvering. Due to their minimal moving parts, overhead cranes are easier to maintain and experience fewer breakdowns, resulting in lower maintenance costs.

Crane Design and Customization

Manufacturers design overhead cranes by considering specific application factors such as workspace dimensions, load weight, usage frequency, application duration, standard requirements, and mobility needs. These considerations influence crucial decisions, including crane dimensions, the choice between single and double girder designs, crane type, and lifting capacity. Overhead cranes are highly customizable, often featuring custom dimensions and special attachments tailored to individual needs. For instance, to meet winch hardware height requirements, manufacturers may design bridge cranes using either a single girder or double girder configuration, resulting in single girder or double girder bridge cranes.

The Future of Remote Crane Monitoring Systems

Wireless remote crane management systems provide operation and safety personnel with accessible data, enhancing productivity and precision. These improvements significantly impact operational forecasting and profitability. Remote crane monitoring systems offer numerous benefits, including rapid and accurate data collection, enhanced safety, increased productivity, and extended service life. They are particularly advantageous for continuous and mission-critical operations but can streamline logistics, reduce space requirements, and lower labor costs in any application, leading to higher revenues.

Traditional crane setups lack real-time information acquisition, requiring authorized personnel to connect a computer to access essential data and detect operational hazards. Operators often rely on hand signals, which is time-consuming and compromises safety. Remote crane monitoring systems eliminate these inefficiencies and safety risks. Additionally, future advancements will further enhance the sophistication, safety, and productivity of crane operations.

As businesses expand, it is essential to enhance capacity accordingly. Consequently, a transport system capable of meeting high demand with safety and efficiency becomes imperative. Future advancements in crane technology will empower businesses to scale operations by incorporating adaptable features. These enhancements encompass accelerated remote diagnostics, improved maintenance monitoring, and automated positioning, allowing for tailored modifications as necessary.

Smart and interactive service panels on cranes facilitate the swift communication of system faults, enabling operators to respond immediately. These intelligent systems also provide recommendations for inspections, preventive maintenance, and part replacements. As a result, they enhance crane availability, prevent costly downtime, and extend the lifespan of the crane and its components, such as wire ropes.

The advent of remote crane monitoring systems has paved the way for the creation of more compact cranes, enabling them to function effectively in restricted spaces. Leveraging wireless communication, these systems ensure precise and secure load positioning, even in difficult-to-access areas. Additionally, the integration of recyclable materials in crane construction has notably decreased manufacturing expenses.

Wireless remote crane management systems offer valuable data to both operational and safety teams, boosting efficiency and enhancing the accuracy of crane movements. These advancements play a crucial role in improving operational forecasting and profitability.

Choosing a Right Overhead Crane

Overhead cranes come in various shapes and sizes to optimize the production process. When selecting the appropriate crane, it is important to consider factors such as the crane’s motion, the type and weight of the load, the location of the crane (whether indoor or outdoor), the intended usage, the required capacity, and the span of the crane.

Crane Safety and Compliance Standards

To ensure the longevity and safe operation of overhead cranes, regular maintenance and inspections are essential, following OSHA’s standardized guidelines. Operators must perform monthly inspections of running ropes and end connections to check for fraying, broken strands, and wear. Daily maintenance includes examining hoist chains and end connections for twisting, distortion, or wear, inspecting hooks for cracks or deformations, checking hydraulic and pneumatic components for leaks, and ensuring operating mechanisms are properly adjusted.

It is crucial to regularly inspect overhead cranes for corrosion, deformation, and cracks. Check drums and sheaves for wear and damage, and monitor for issues like loose bolts or rivets, sprocket and chain wear, brake part and system wear, and general part distortion. Keep a crane kit on hand for quick replacement of these system elements. Additionally, it is essential to regularly review the condition of electric and fossil fuel motors, indicators, and electrical components, including limit switches and pushbuttons. For safety reasons, only a certified and trained individual should operate the crane due to the complexity and risks associated with this task.

Mobile Elevated Work Platform Inspection

Mobile Elevated Work Platforms (MEWPs) are commonly used in warehouses to facilitate safe work at various heights. To ensure the safety and reliability of MEWPs, inspection courses play a crucial role. These courses enable employees to prevent unnecessary accidents by teaching them good maintenance regimes for equipment, how to apply OSHA inspection standards, and how to identify and document faults. Additionally, hands-on inspection training and recommendations for safer MEWPs are provided, further enhancing workplace safety.

OSHA Safety Certificate

The OSHA Safety Certificate is essential for ensuring the occupational safety and health of employees, encompassing both Construction (1926) and General Industry (1920) standards. This certification provides comprehensive guidance on utilizing the Federal Register and addresses potential health risks in the workplace. It emphasizes the importance of identifying and mitigating workplace hazards that do not comply with OSHA standards, and it also involves designing tailored safety and health protocols specific to one’s work environment.

Things to Consider About Cranes

When purchasing an overhead crane, it’s essential to work with an experienced and reliable manufacturer. Failing to do so could result in a mismatched crane or even serious accidents.

To find a trustworthy manufacturer, review the profiles of crane companies we recommend. Beforehand, list your specifications, budget, delivery timeline, and standard requirements. Compare and contrast these criteria with the companies listed. Select three or four potential matches and reach out to them, preferably via phone, to assess their customer service. After evaluating their offers, choose the manufacturer that best meets your needs.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches