A gantry crane is an overhead crane that has two more beams that are supported by legs. These cranes move on wheels, tracks, or rails. Gantry cranes are used widely in workshops, warehouses, shipyards, and railroads. Gantry cranes are designed in a way to carry small loads as well as heavy-duty ones. Read More…

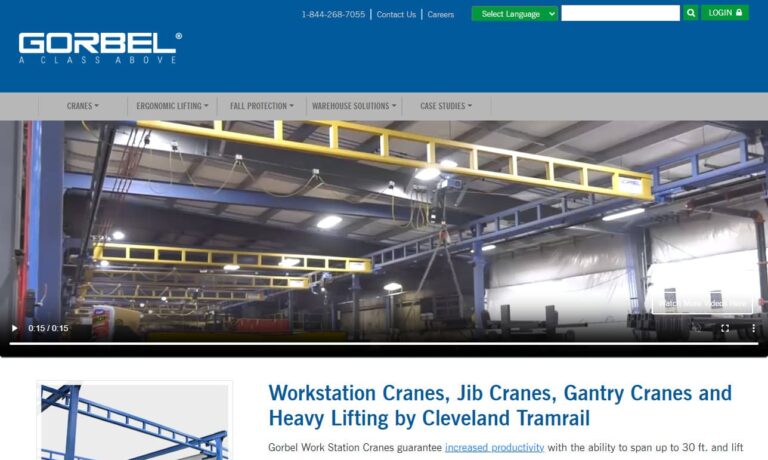

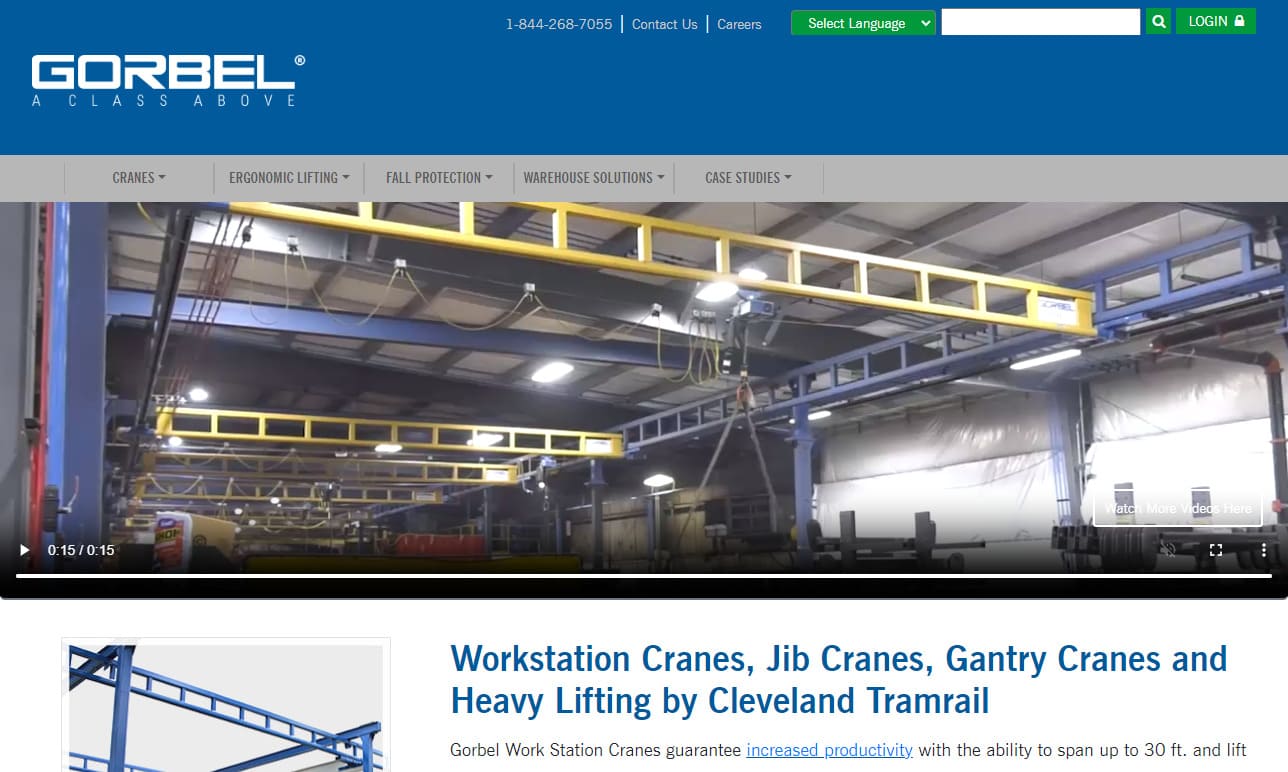

Gorbel®, Inc. is an innovator and leader in producing bridge cranes for the industry. Gorbel® provides a wide variety of overhead handling solutions that handle loads from fifty pounds up to forty tons. Contact us today and we will work with you to find the best product for your unique application. Call or visit our website for additional information.

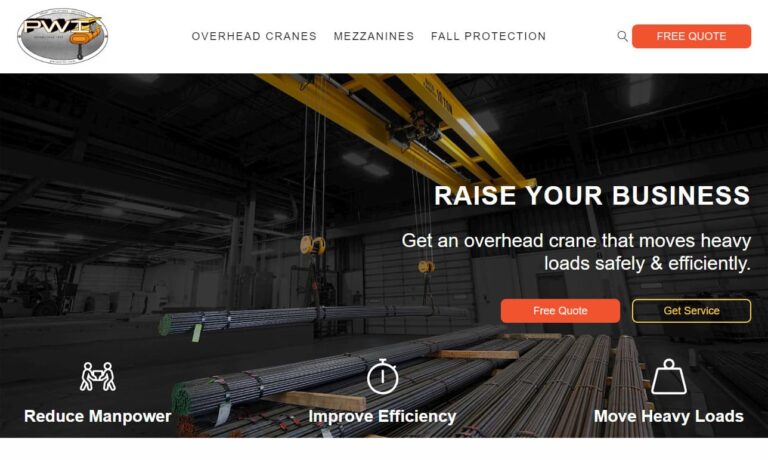

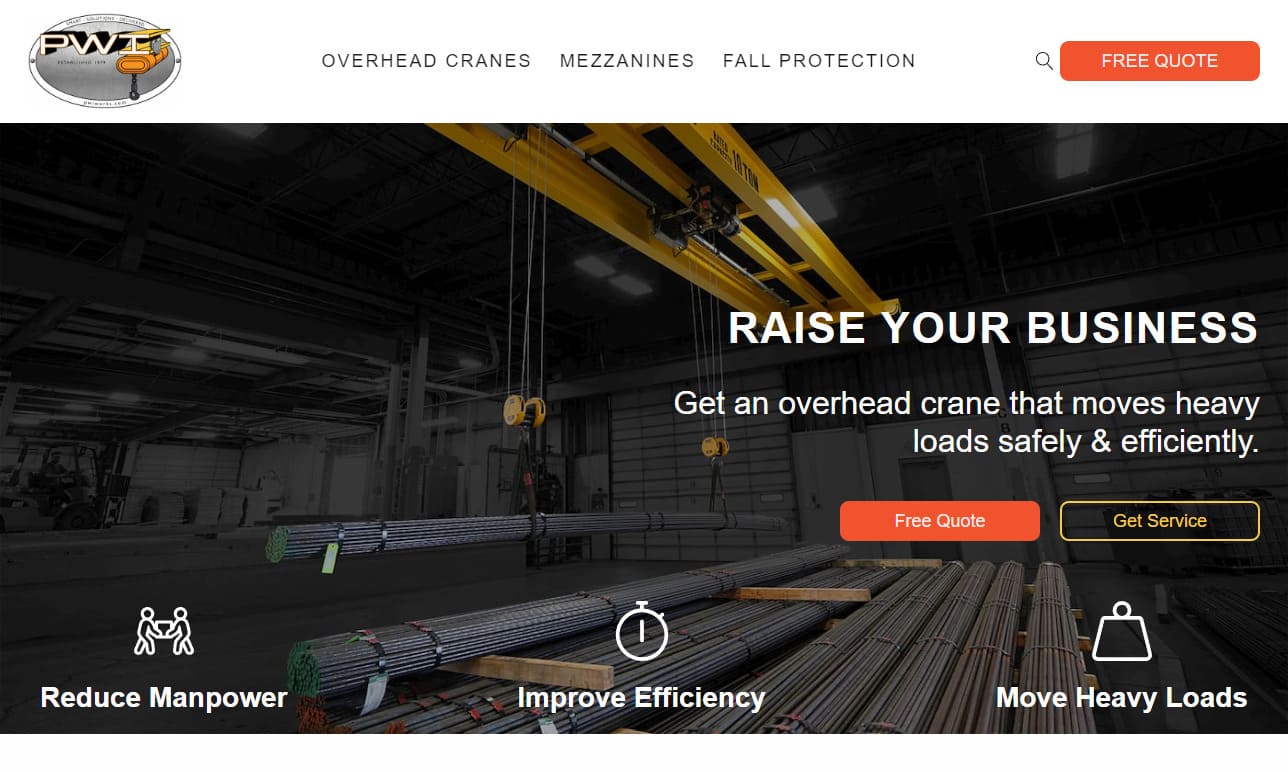

PWI cranes are ready to help with any of your material handling needs. Our overhead bridge cranes are typically for heavy-duty material handling needs. Workstation cranes are lightweight and can be installed in any workspace. Jib cranes provide an excellent way to transfer material from on station to another. Gantry cranes work great for moving overhead cranes to different areas. Our team is...

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

We are Givens Lifting Systems, Inc., a leading company specializing in providing high-quality lifting solutions, with a primary focus on cranes. With our extensive expertise and commitment to innovation, we have established ourselves as a trusted partner for various industries worldwide.

At Simmers, we can take a new crane project from start to a turnkey finish. We will supply all equipment through our network of vendors and fabricate the crane at one of our facilities. We also offer field installation after the crane is built. Our highly qualified and trained staff will design a crane that meets your needs and CMAA design standards. For more information on how Simmers crane can...

Bridge Crane is a problem-solving organization that specializes in customized design, manufacturing, installation, and servicing of overhead and work station crane systems. We are dedicated to safety, efficiency, and practical solutions to meet our customer’s material handling needs.

More Gantry Crane Manufacturers

Gantry cranes are classified as single girders and double girders. The single girders are designed to carry smaller loads and double girders are designed to carry heavy-duty loads. It means, the higher the capacity of the crane, the greater the performance will be.

Gantry cranes are available in a variety of shapes, such as the “A” frame and sometimes with “L” and “U” shaped legs. However, the most commonly used is the “A” shaped one. All gantry cranes are designed to lift light and heavy loads whether they are single girder or double girder. However, double girder gantry cranes are more expensive compared to single girder ones.

The lifting capacity of gantry cranes ranges from a few hundred pounds to several hundred tons. The height of gantry cranes is either fixed or adjustable depending on the type of object to be lifted and the working environment.

Construction of Gantry Cranes

The components of a gantry crane, whether a small one or a huge one, are divided into three categories:

- Mechanical

- Structural

- Electrical

Girders or beams are present in all types of gantry cranes positioned off the floor and parallel to the ground. The girders, frame, and legs are the essential part of these cranes. The legs of a gantry crane can be a straight beam, truss beam, or A-frame. These components differentiate the gantry cranes from overhead or bridge cranes.

Components of Gantry Cranes

Below are the components of the gantry cranes:

Frame

The gantry crane consists of the main girder and its legs, whereas the semi-gantry crane has one leg. The size, length, and number of beams depend on the load’s weight. One side of the leg is rigid, and the other one is flexible to reduce the dead weight of the load.

Trolley

The hoist is moved by the trolley horizontally along the girder or may be attached to the top or underside. The trolleys are of three types: low, normal headroom, and double girder. Some trolleys came with space washers and can be adjusted by adding or removing the washers. The trolley collision can be prevented by using wheel bumpers and side guide rollers to prevent it from wobbling.

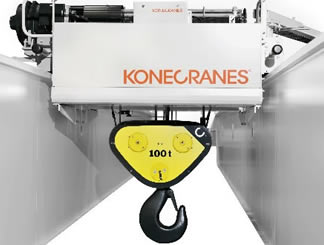

Hoist

The hoist is mounted on the trolley to lift and lower the load along the vertical plane. The chain-driven hoist can lift up to five tons of a load, while the wire rope hoist can lift five tons or greater.

Power

A form of wiring called festoon powers the trolley and the hoist. Cables are used to send the power from the panel to the hoist. The power can be direct AC or induction AC.

Controls

The operator gets all the controls of the gantry crane and drives it with the help of remote control or a pendant. It has buttons, levers, or other commanding mechanisms to move the gantry crane.

Types of Gantry Cranes

The types of gantry cranes are divided based on their configuration, design, and weight capacity. These are:

Full Gantry Crane

This type is the normal configuration of the gantry crane with a cross beam, legs, and hoist. These run on wheels, rails, or a track. Depending on the size, these cranes are mobile and portable.

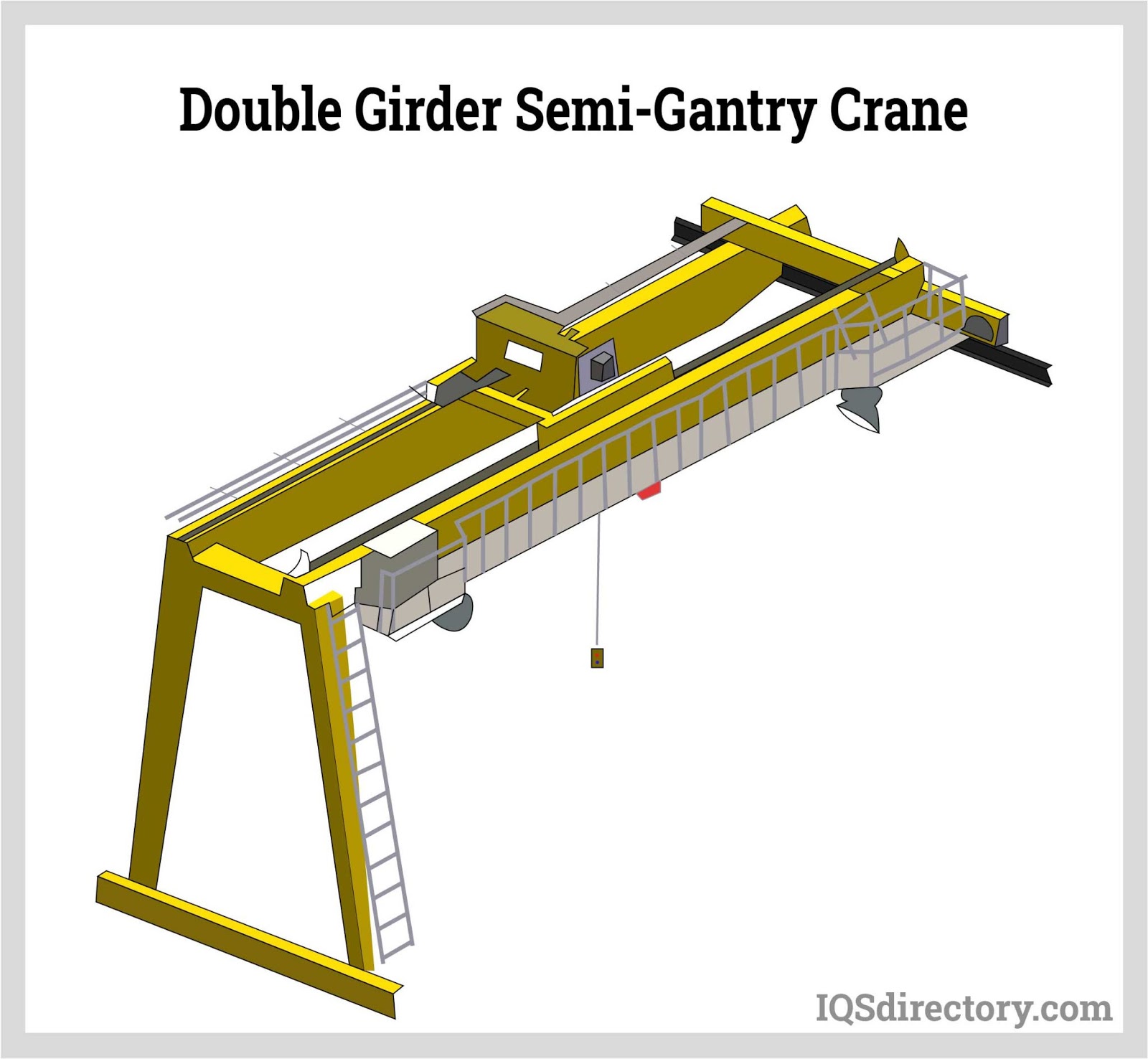

Semi-Gantry Crane

This crane has one leg, and a wall-mounted I beam that supports the other side of the crane. These cranes are a combination of overhead and gantry cranes. These cranes are installed indoors and outdoors, sometimes under overhead cranes, to increase work efficiency.

Portable Gantry Crane

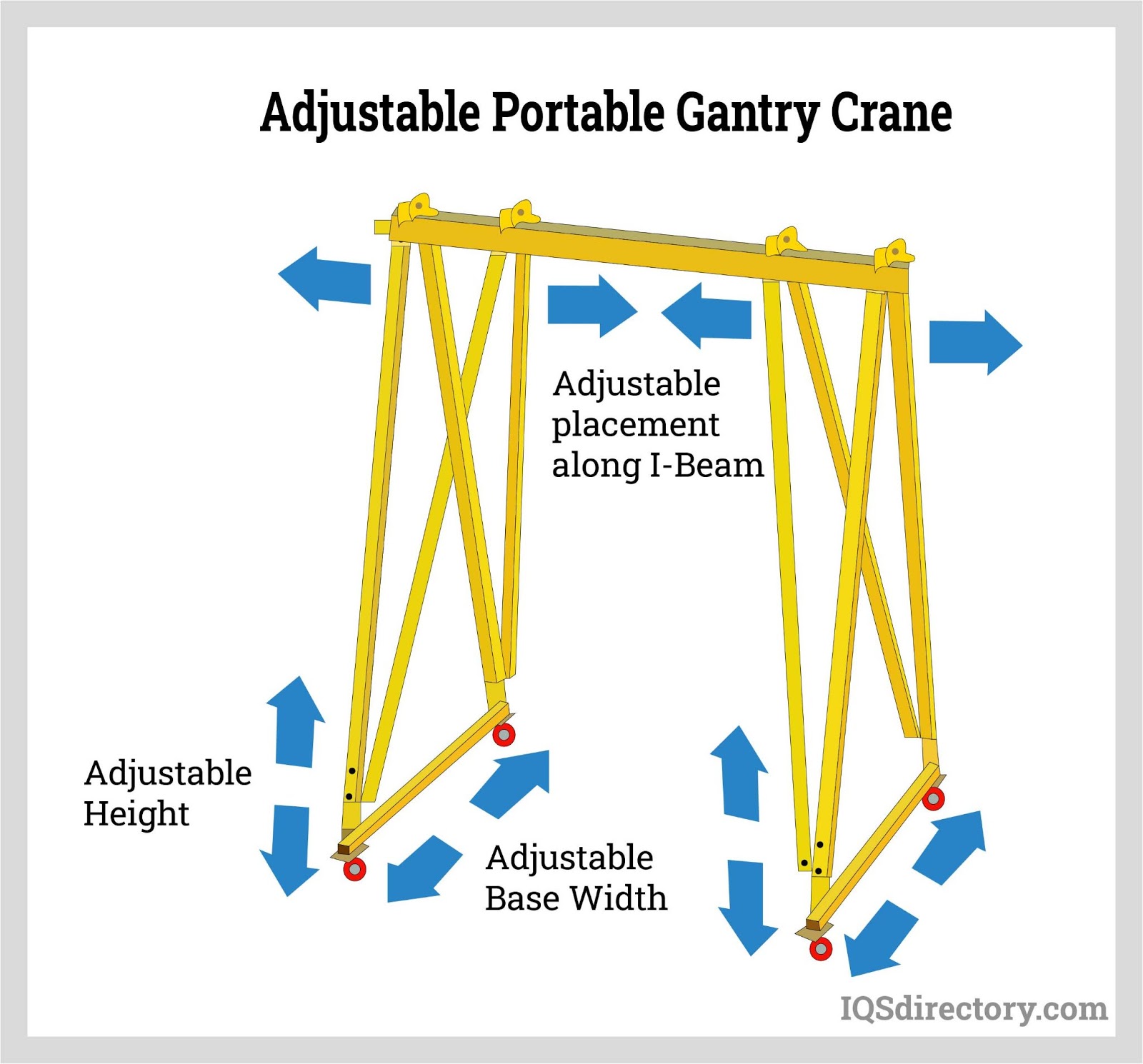

Portable gantry cranes are lightweight and mounted on rubber wheels. The lifting capacity of these cranes is from half a ton up to five tons. These cranes can be moved to any place for lifting purposes.

Adjustable Gantry Crane

There are various adjustable gantry cranes, such as portable or fixed. The dimensions of these cranes can be adjusted according to the load requirements.

Single Girder Gantry Crane

This crane has one bridge beam with a hoist trolley that runs on the lower portion of the crane. Its components are a beam, support legs, hoist, crane drive, controls, and cross beams.

Double Girder Gantry Crane

This crane has two girder beams that make up the bridge, and the trolley runs on the top or under the beam. These are designed for heavy duty applications. These cranes have strong bearing capacity, large spans, and stability.

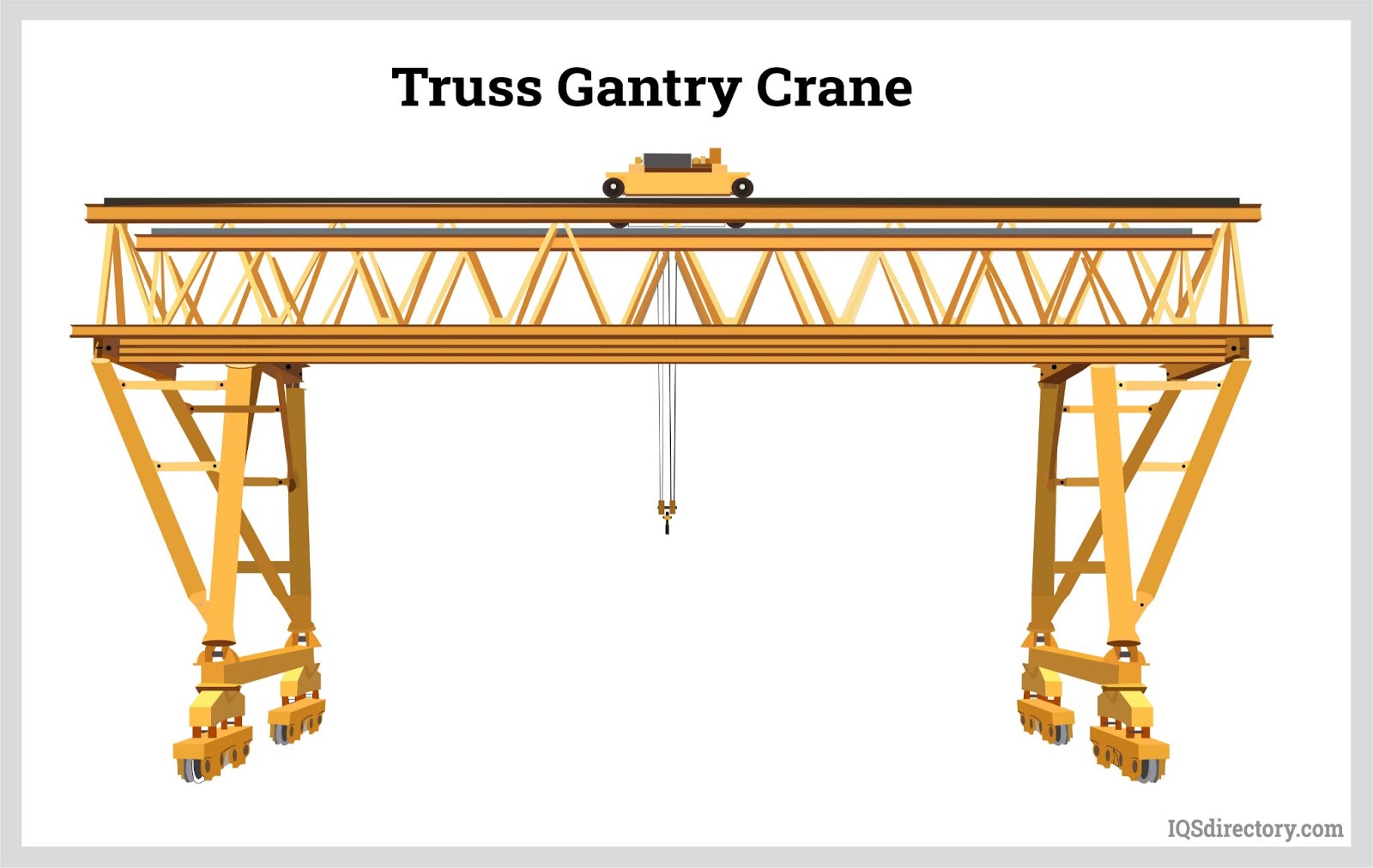

Truss Gantry Crane

It has a latticed structure, lightweight, good lifting ability. It is best to use in a warehouse for lifting equipment.

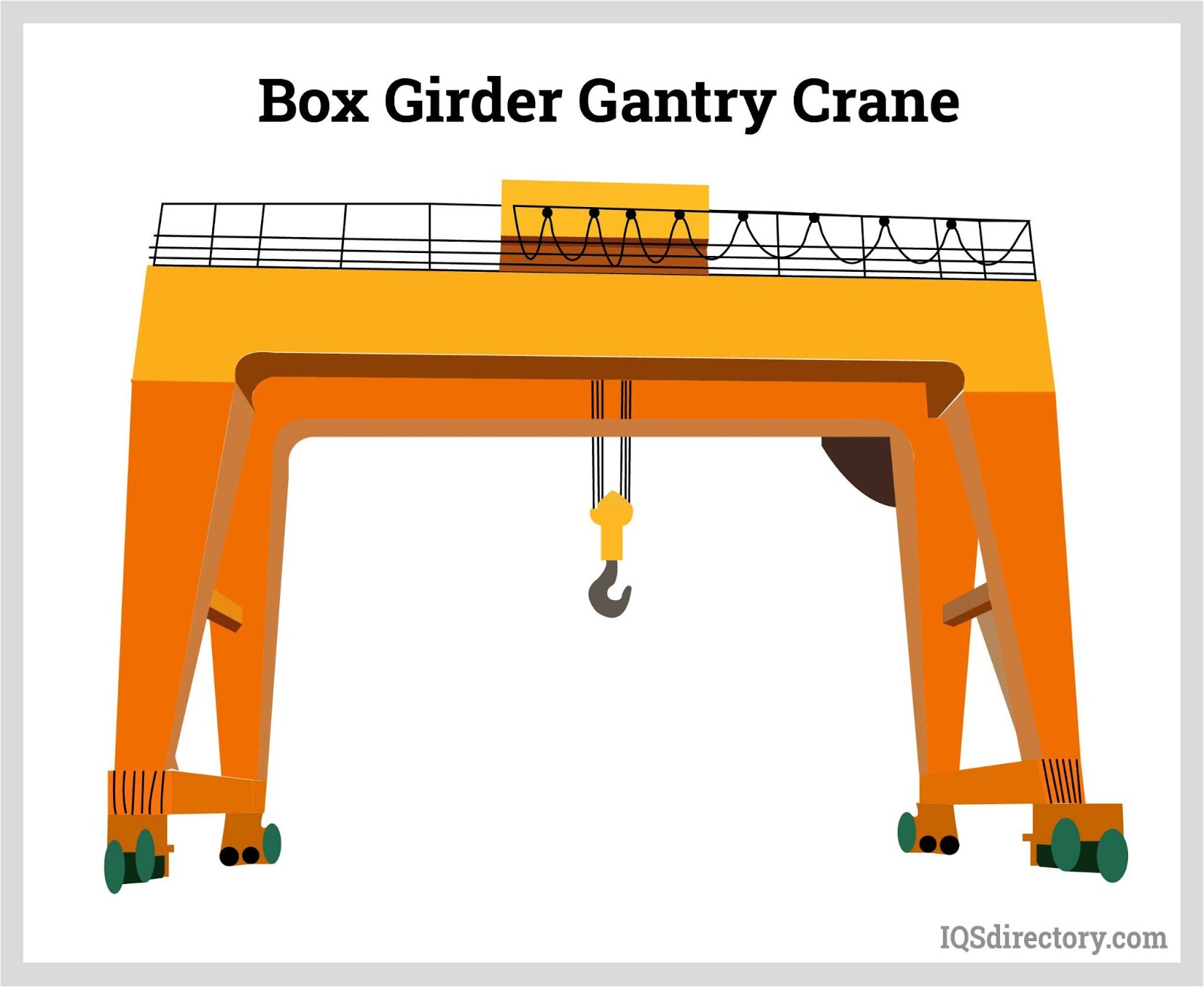

Box Gantry Crane

These are placed in areas where overhead cranes cannot work well. These can be double-box or single-box designs. Double-box designs are used for lifting extremely heavy objects.

L-Shaped Gantry Crane

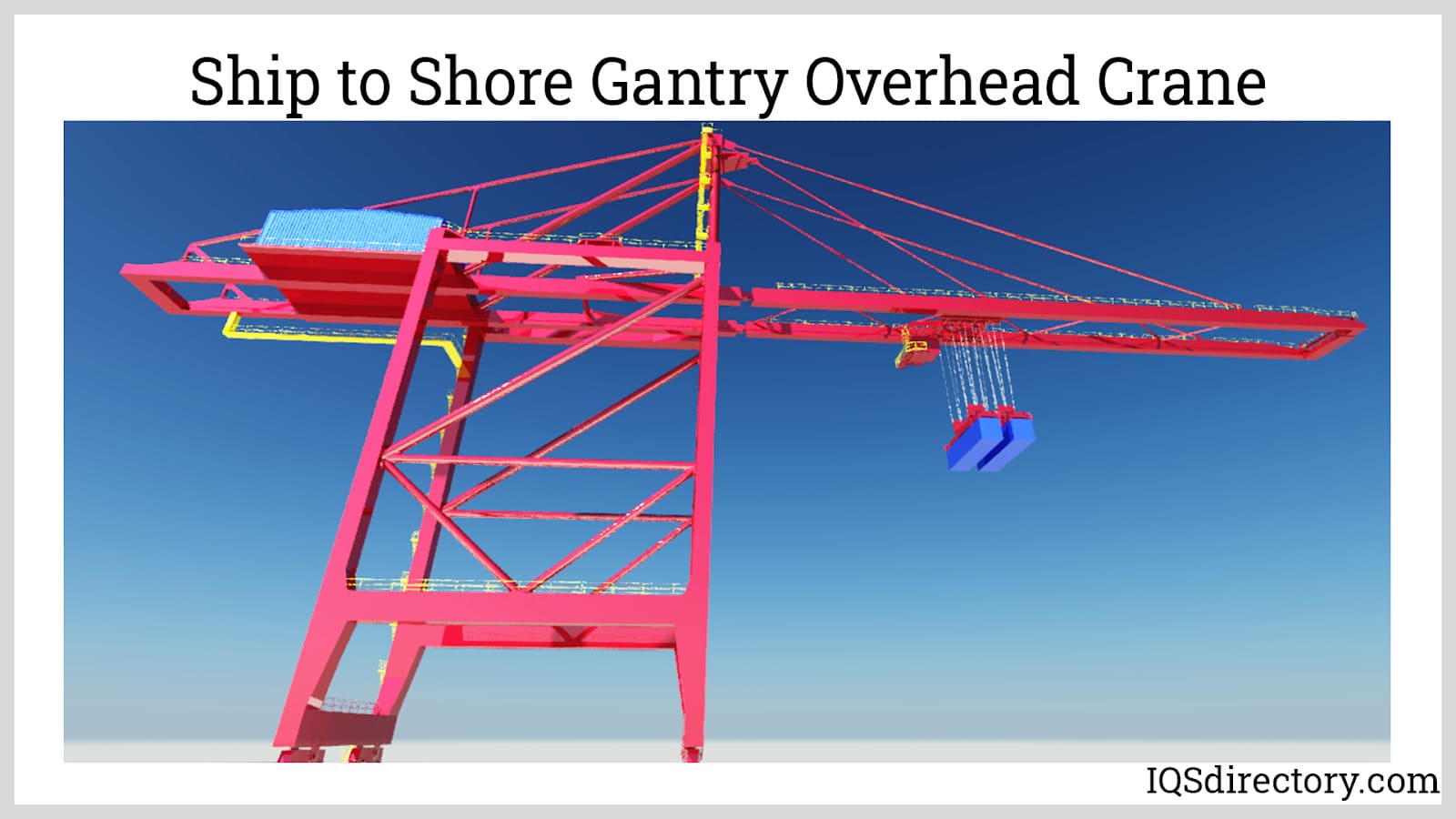

L-shaped gantry cranes have attached hooks that help lift objects and load at seaports or warehouses.

U-Shaped Gantry Crane

U-shaped gantry cranes have more space between the legs and are used for lifting heavy duty loads.

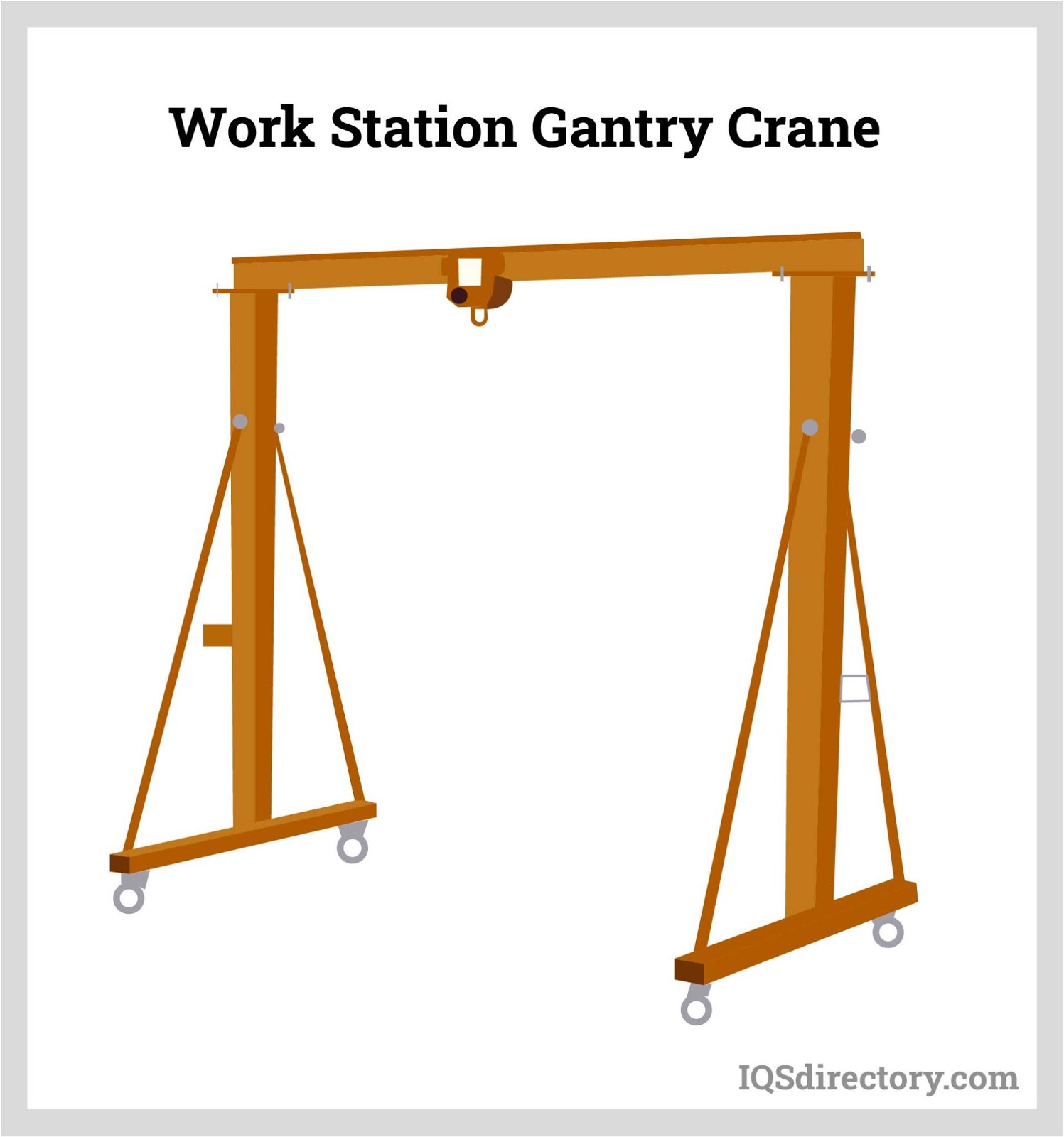

Workstation Gantry Crane

These are industrial cranes with moving bridges that run across parallel runways. These are attached with a hoist, manipulators, or intelligent lifting devices for lifting loads.

Uses of Gantry Cranes

Gantry cranes are widely used in the industrial sector for lifting and placing heavy or lightweight loads. These are used in railroads, automotive manufacturing facilities, or shipyards to speed up the lifting process with ease.

Choosing the Correct Gantry Cranes Supplier

To make sure you have the most constructive outcome when purchasing Gantry Cranes from a Gantry Cranes Supplier, it is important to compare at least 4 Manufacturers using our list of Gantry Cranes suppliers. Each Gantry Cranes Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Gantry Cranes company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Gantry Cranes businesses with the same form.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches