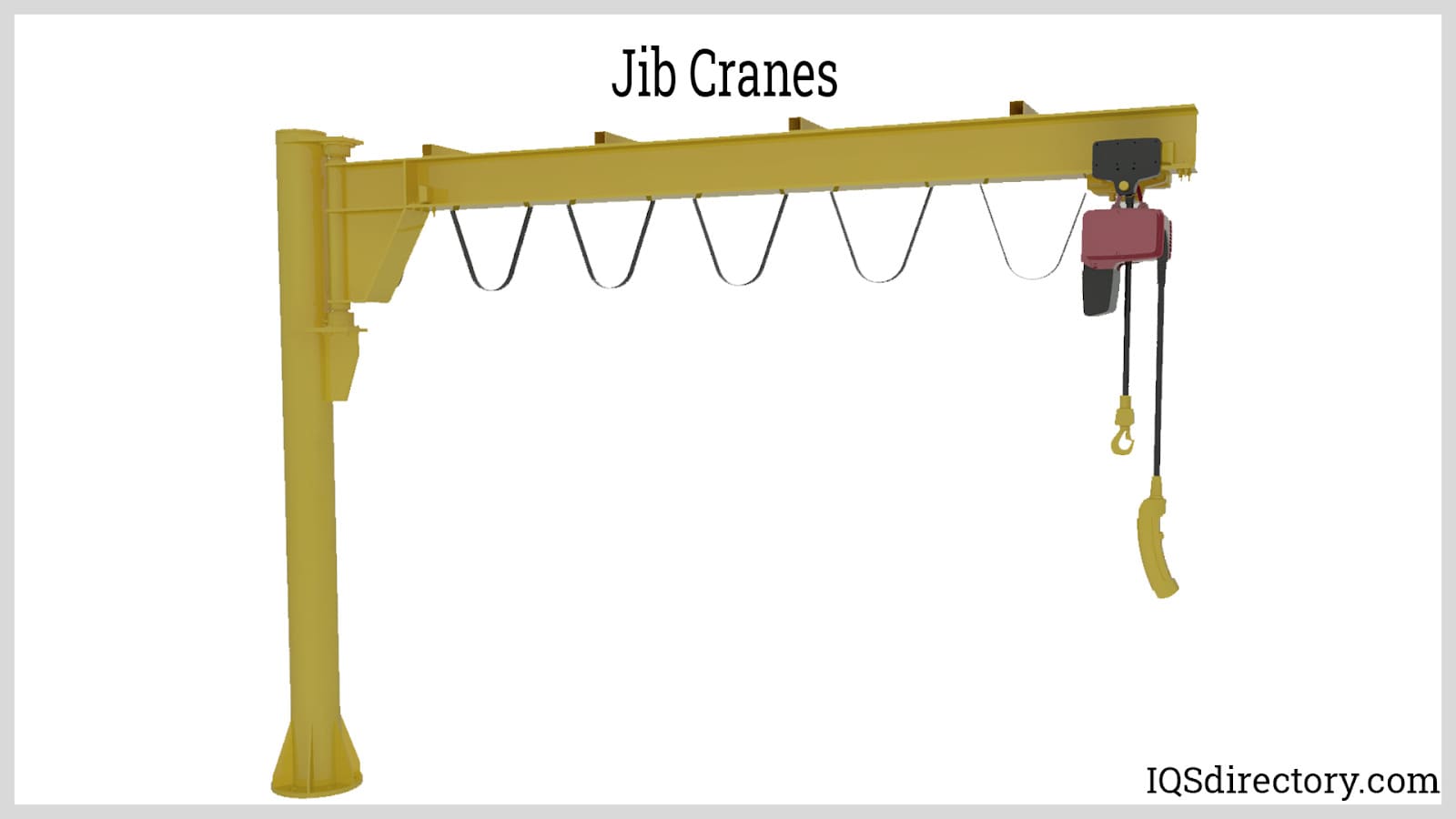

The arm or boom of a jib crane extends off the main body to give additional reach, and it features a lattice construction to reduce the weight of an increased load. Because of its design, jib cranes can perform repetitive lifting duties efficiently in tiny work areas. Read More…

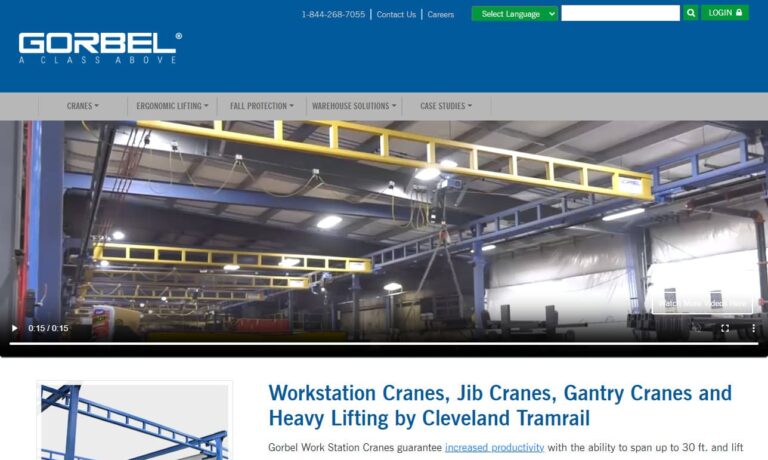

Gorbel®, Inc. is an innovator and leader in producing bridge cranes for the industry. Gorbel® provides a wide variety of overhead handling solutions that handle loads from fifty pounds up to forty tons. Contact us today and we will work with you to find the best product for your unique application. Call or visit our website for additional information.

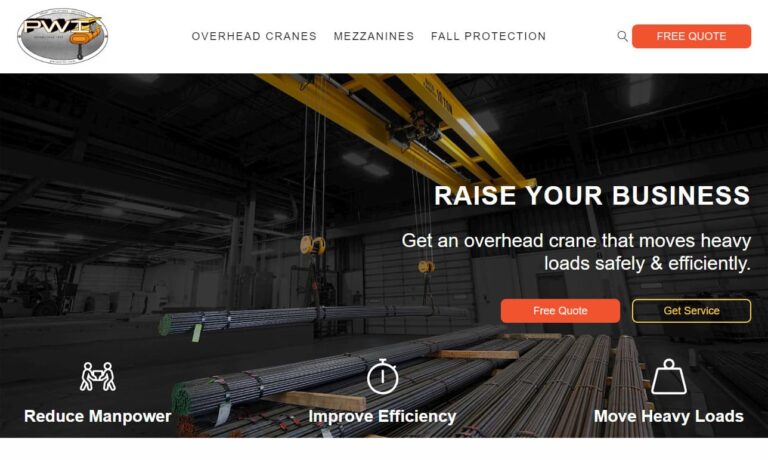

PWI cranes are ready to help with any of your material handling needs. Our overhead bridge cranes are typically for heavy-duty material handling needs. Workstation cranes are lightweight and can be installed in any workspace. Jib cranes provide an excellent way to transfer material from on station to another. Gantry cranes work great for moving overhead cranes to different areas. Our team is...

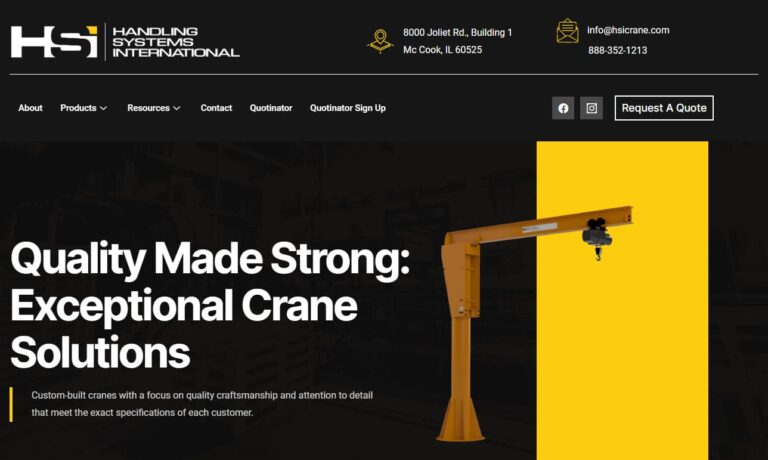

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

We are Givens Lifting Systems, Inc., a leading company specializing in providing high-quality lifting solutions, with a primary focus on cranes. With our extensive expertise and commitment to innovation, we have established ourselves as a trusted partner for various industries worldwide.

At Simmers, we can take a new crane project from start to a turnkey finish. We will supply all equipment through our network of vendors and fabricate the crane at one of our facilities. We also offer field installation after the crane is built. Our highly qualified and trained staff will design a crane that meets your needs and CMAA design standards. For more information on how Simmers crane can...

Bridge Crane is a problem-solving organization that specializes in customized design, manufacturing, installation, and servicing of overhead and work station crane systems. We are dedicated to safety, efficiency, and practical solutions to meet our customer’s material handling needs.

More Jib Crane Manufacturers

They are incredibly adaptable and flexible cranes with a straightforward design that can lift anything from 250 lbs. to 15 tons.

Tower cranes are among the most recognized and noticeable jib cranes. The building of skyscrapers and other very huge structures is done with the help of these cranes. They have a single, extremely tall support platform and a single, perpendicularly-positioned, off-center jib arm. A cab is positioned where the tower support and jib arm meet, making it possible to control the tower. The winch or hoist mechanism, which raises things by attaching them to an incredibly strong cable, is located on one end of the jib. A balancing weight, often consisting of numerous concrete slabs, is attached to the jib arm’s other end.

If nothing stands in their way, tower cranes can spin 360 degrees. Telescoping cranes, loading cranes, and tiny dock-mounted cranes are some more jib crane variants.

Components of a Jib Crane

The components used in the construction of a jib crane include:

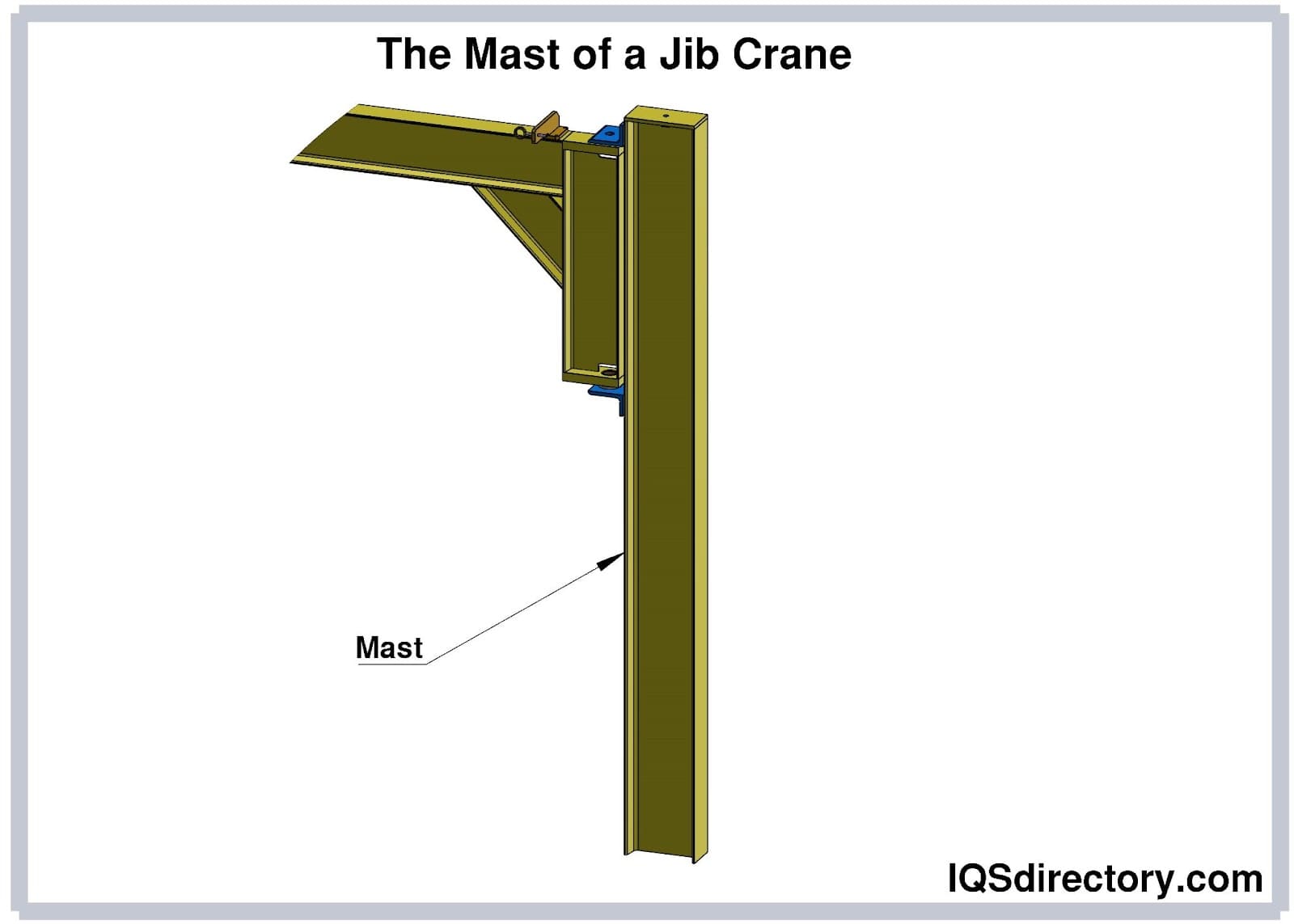

- Mast Components

- Jib Crane Boom

- Hoist in a Crane

- Crane Trolley

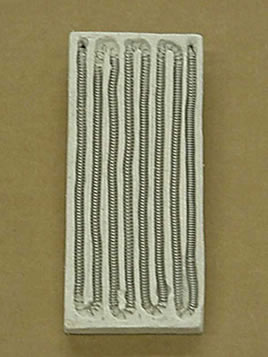

- Festoon System

- Power for Jib Cranes

- Rotation Stop

Types of Jib Cranes

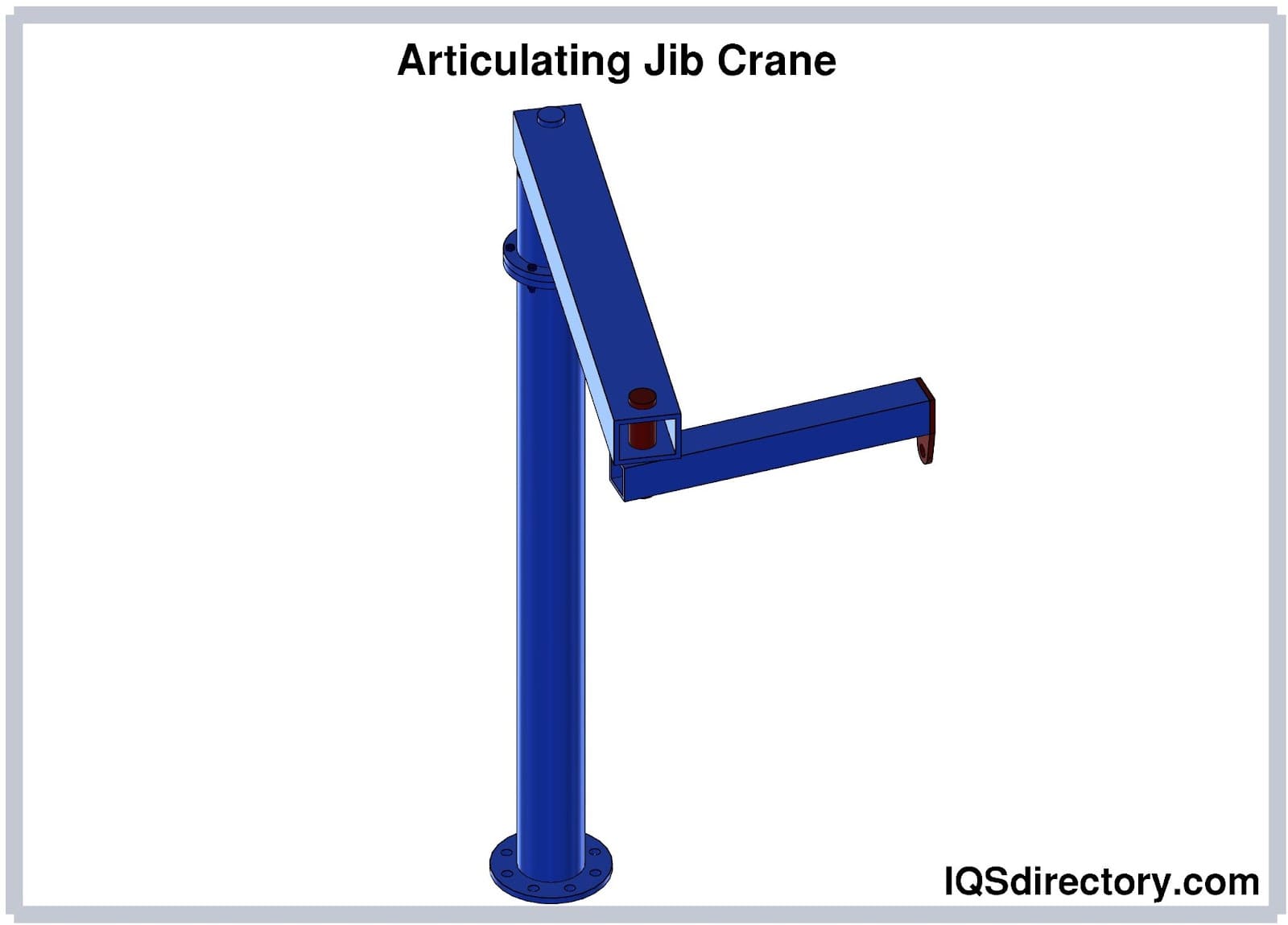

Articulating

A jib crane with articulation has a single boom and two swivel arms. To reach underneath and inside machinery and containers, one uses the arms. One arm can be rotated 360 degrees, while the other allows for 200 degrees rotation.

Freestanding

This kind of jib crane is the most common. Because it is movable, it may be put anywhere, both indoors and outside.

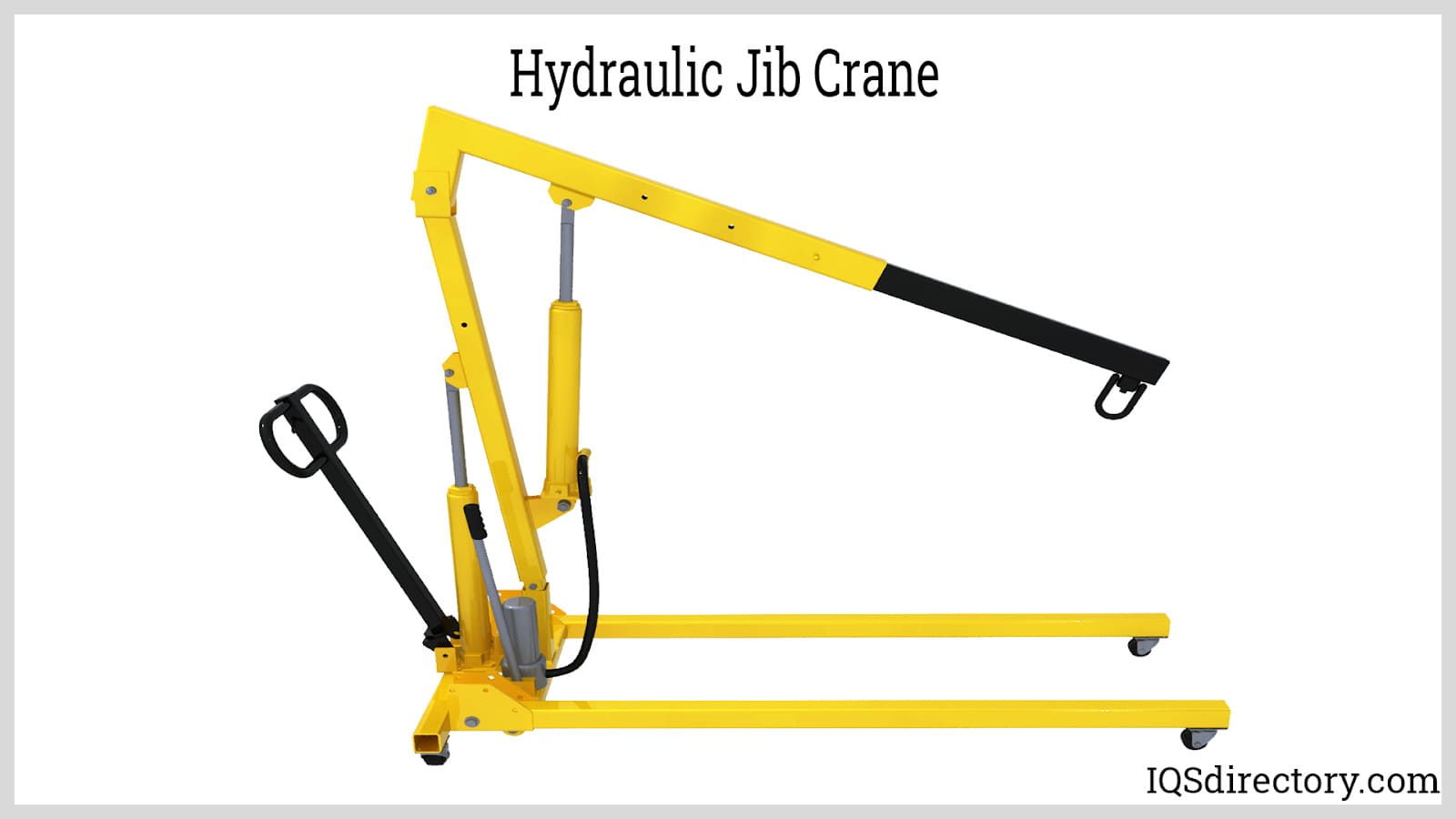

Hydraulic Jib Crane

A hydraulic jib crane is a portable jib crane that can lift and lower its arm using a hydraulic cylinder.

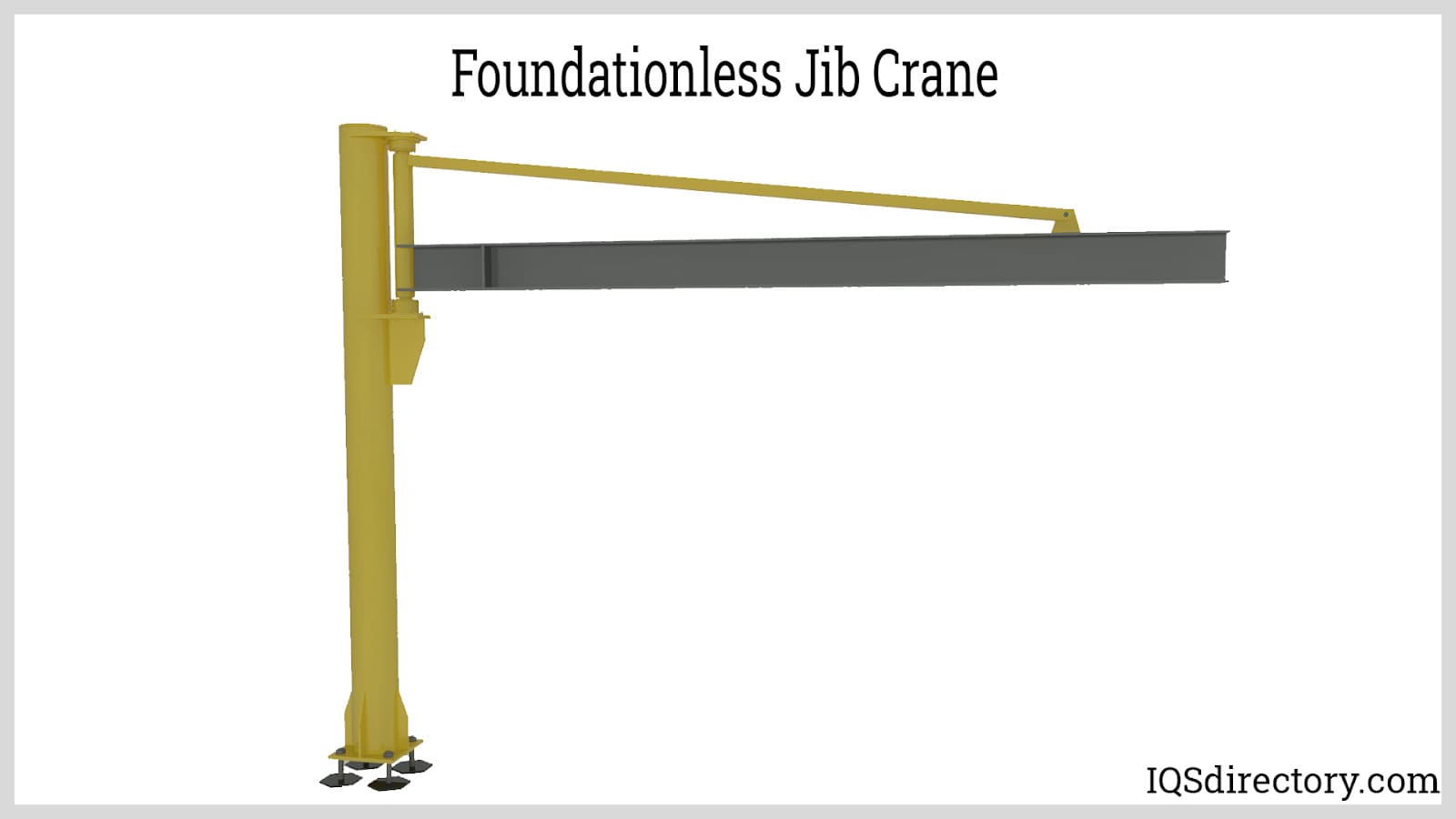

Foundationless

This form of the freestanding jib is attached to 6-inch reinforced concrete and fixed on a slab. This crane is utilized indoors and doesn't need a special base.

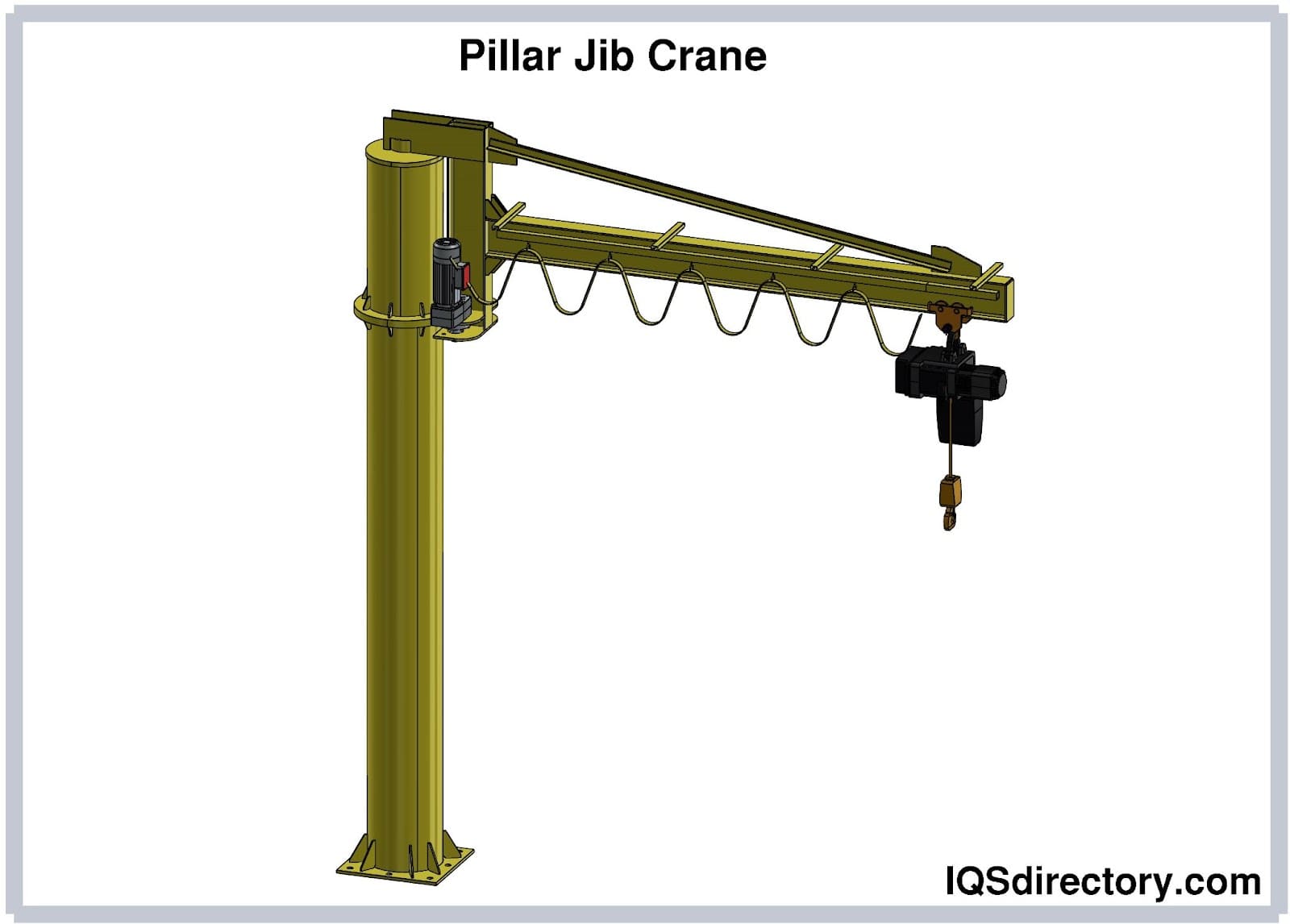

Mast Kind

These are also incredibly cost-effective because they don't need a certain foundation type. Only 6 inches of reinforced concrete are required to hold them. An above support structure or beam may offer additional assistance.

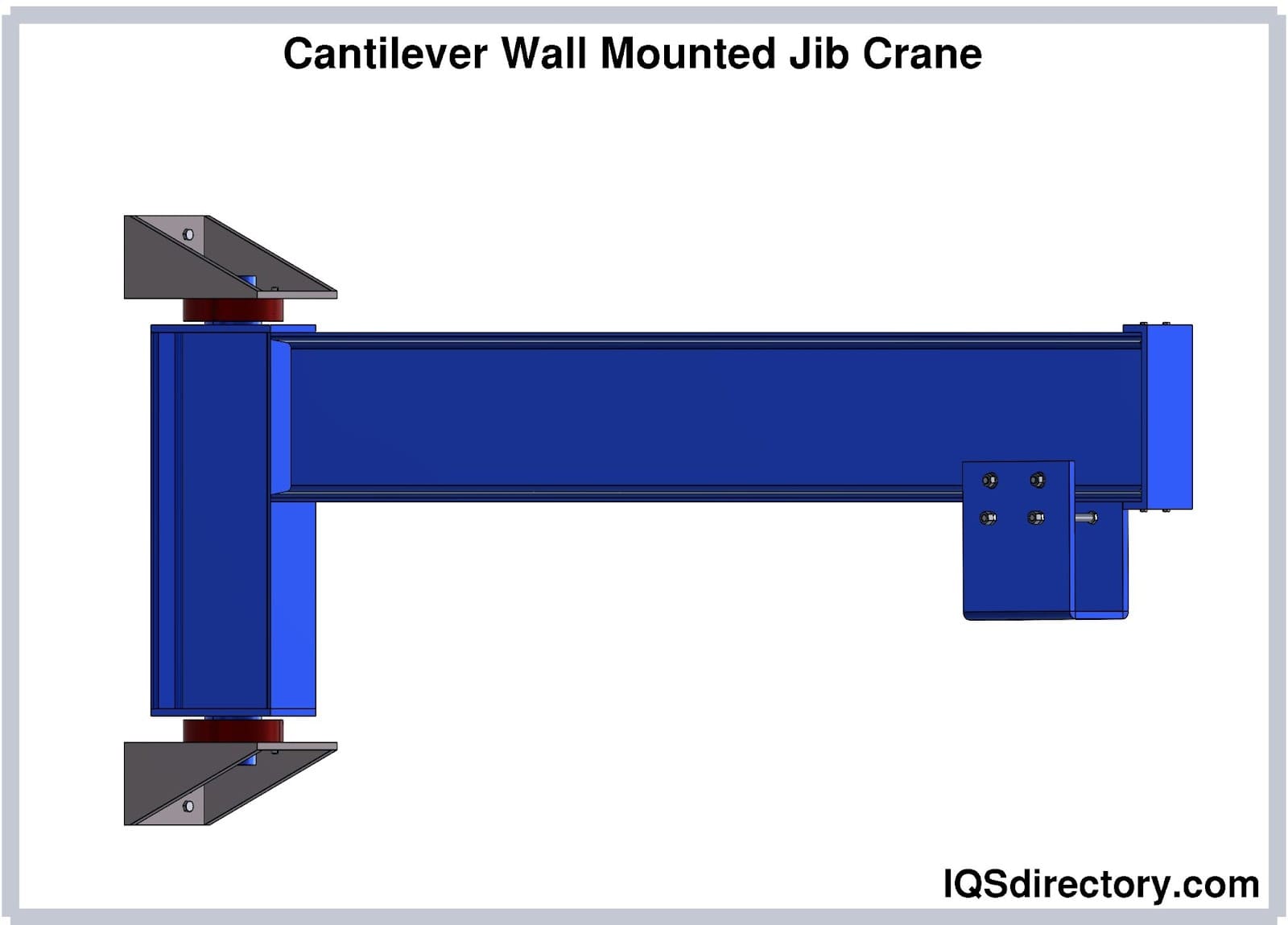

Wall-Mounted

Wall-mounted cranes are simple to install and do not need a base. They can be utilized in individual bays, on walls, as building support columns or to complement overhead bridge cranes. They are limited to a 200-degree rotation, though.

Construction of Jib Cranes

- Jib cranes are made of a beam and a boom as their fundamental structure, with other parts added to improve and streamline the crane's function.

- Various accessories have been added to jib cranes to meet the requirements of the processes they were created; some have trolleys and electrical controls, while others are controlled by wire ropes, levers, and chains.

- Many elements go into the design and building of jib cranes, and each one is an advancement for worker safety and productivity.

- Jib cranes have been designed, created, and altered from their fundamental design to accommodate various lifting purposes.

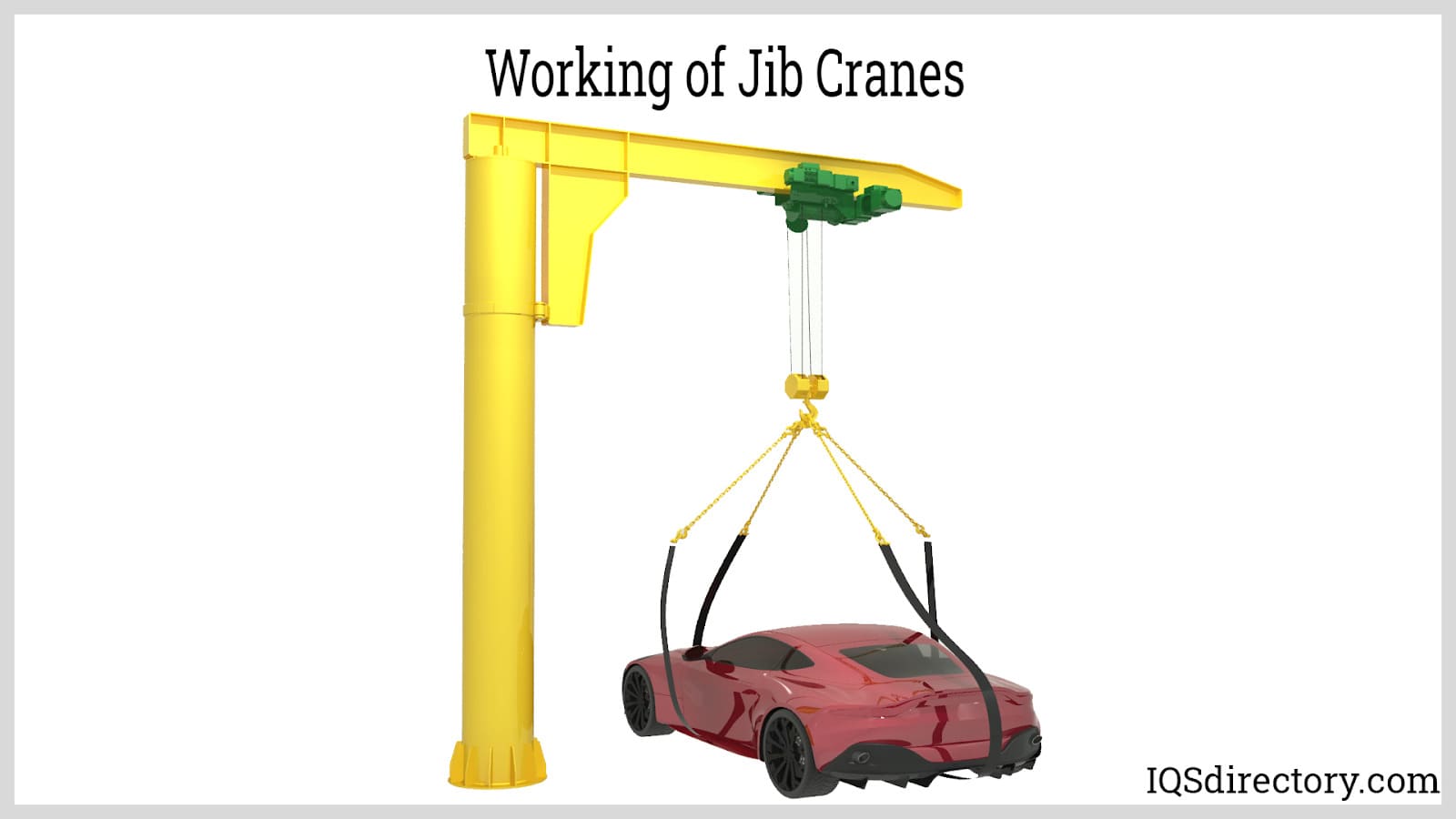

Working of Jib Cranes

- All jib cranes can lift or support weight and rotate.

- The majority of jib cranes also traverse, which means that when the jib crane rotates, it may move the beam from the circle's center to its periphery.

- Jib cranes frequently feature a hand-powered rotation and traverse action, whereas a hand-powered or electric-powered lift motion is typical.

- Push/pull is used to power the hand-powered rotation and traverse action, while a chain like that of a manually-operated garage door is used to power the hand-powered lifting.

- Almost all jib cranes include options for motorized rotation and traverse.

Benefits of Jib Cranes

- Jib cranes have significantly reduced the workload on staff and increased production.

- This crane offers a variety of simple options to customize your multifunctional venue.

- It has 2,000 kg (over 4,400 lb) of efficient and precise load handling

- Modern ergonomic elements may be adjusted to improve the operator experience.

- Jib cranes have a longer lifetime and fewer maintenance needs

- Its simple maintenance reduces downtime

Applications of Jib Cranes

- Jib cranes are positioned close to manufacturing lines for material handling and transport and are placed up at workstations to help employees with assembly activities.

- Gantry and overhead cranes, which can travel the whole length of a complex and hoist enormous loads, are cranes frequently seen in warehouses and supply storage facilities.

- Jib cranes enable the manufacture of small car parts as well as huge buildings in manufacturers.

- Jib cranes have historically been used to load and unload vehicles and ships in various methods.

- Jib cranes have countless uses and applications because of their capacity to lift precisely and position large items awkwardly.

Choosing the Correct Jib Cranes Company

To make sure you have the most beneficial outcome when purchasing Jib Cranes from a Jib Cranes Supplier, it is important to compare at least 4 Companies using our list of Jib Cranes manufacturers. Each Jib Cranes Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Jib Cranes company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Jib Cranes businesses with the same message.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches