Using the overhead area of a manufacturing plant, an overhead crane is a form of heavy-duty machinery that can safely and accurately transport extremely large goods and equipment from one place to another. They are precisely constructed and intended to match a certain loading application because of the nature of their task. Read More…

Gorbel®, Inc. is an innovator and leader in producing bridge cranes for the industry. Gorbel® provides a wide variety of overhead handling solutions that handle loads from fifty pounds up to forty tons. Contact us today and we will work with you to find the best product for your unique application. Call or visit our website for additional information.

PWI cranes are ready to help with any of your material handling needs. Our overhead bridge cranes are typically for heavy-duty material handling needs. Workstation cranes are lightweight and can be installed in any workspace. Jib cranes provide an excellent way to transfer material from on station to another. Gantry cranes work great for moving overhead cranes to different areas. Our team is...

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

We are Givens Lifting Systems, Inc., a leading company specializing in providing high-quality lifting solutions, with a primary focus on cranes. With our extensive expertise and commitment to innovation, we have established ourselves as a trusted partner for various industries worldwide.

At Simmers, we can take a new crane project from start to a turnkey finish. We will supply all equipment through our network of vendors and fabricate the crane at one of our facilities. We also offer field installation after the crane is built. Our highly qualified and trained staff will design a crane that meets your needs and CMAA design standards. For more information on how Simmers crane can...

Bridge Crane is a problem-solving organization that specializes in customized design, manufacturing, installation, and servicing of overhead and work station crane systems. We are dedicated to safety, efficiency, and practical solutions to meet our customer’s material handling needs.

More Overhead Crane Manufacturers

There are several sizes, styles, combinations, forms, and components for overhead cranes. They are employed when loading and unloading, transporting objects, removing dies from stamping equipment, or feeding raw materials.

Efficiency and safety are the two basic justifications for deploying an overhead crane. Overhead cranes can work much more quickly than land-based or floor-based equipment. With hot metals, chemicals, or poisonous materials, overhead cranes can transfer things securely and without exposing personnel to risky, extreme situations.

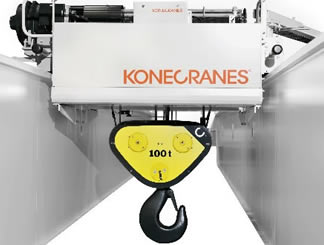

Components of an Overhead Crane

The overhead crane is comprised of:

- Hoist

- Trolley under running/underhung

- Top running

- Bridge – single girder or double girder

- Runway rail or tracks

- End trucks

- Bumpers

- Controls

- Electrification

Types of Overhead Crane

Bridge Cranes

The most popular type of bridge crane on the market is the overhead model. Two above runway beams on a bridge crane are connected to the building's support framework. There are two girder configurations available for this crane: single and double.

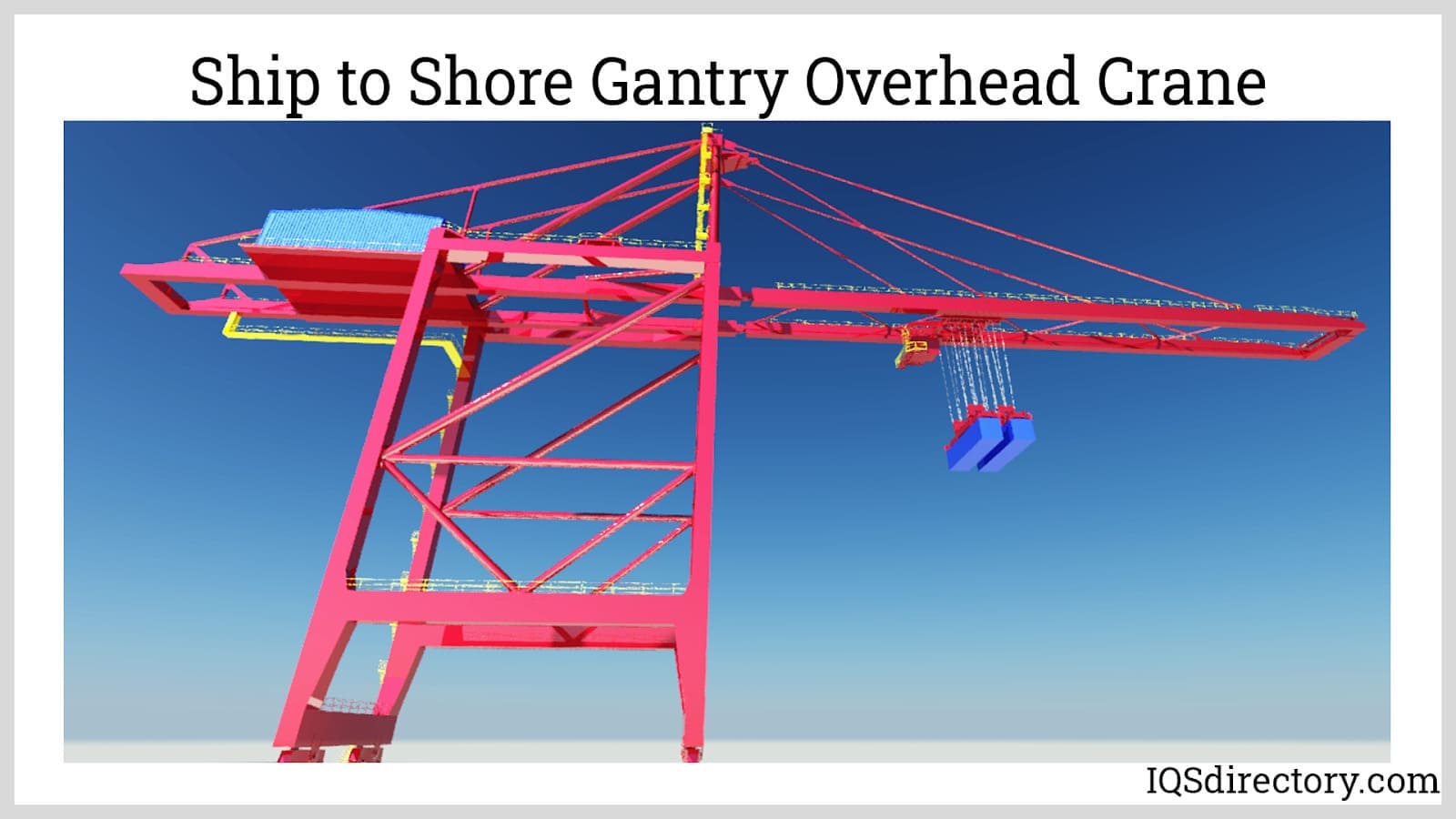

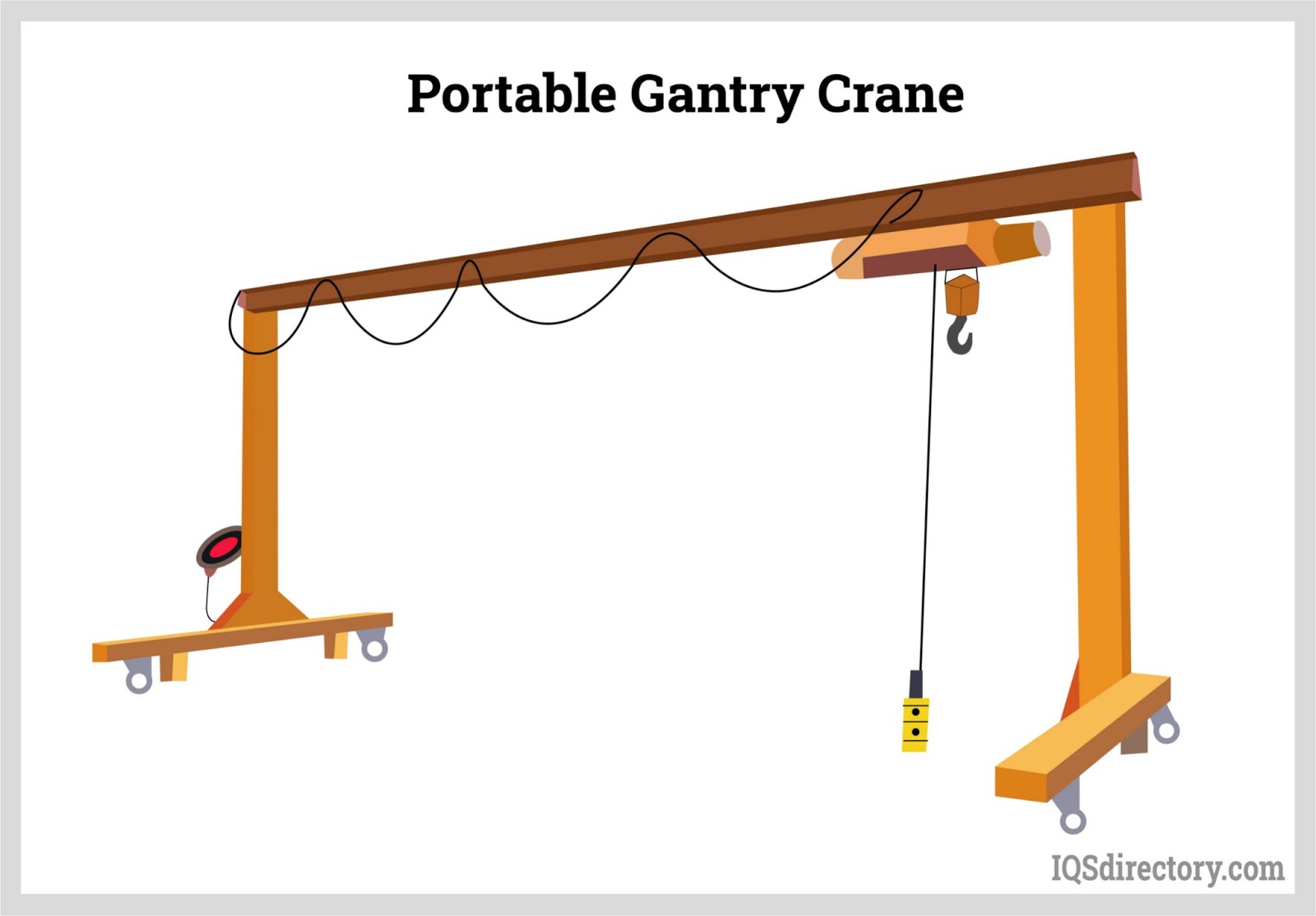

Gantry Cranes

Rather than being suspended from a support beam, the girder in a gantry crane stands on legs. The legs can be installed on, or below, ground.

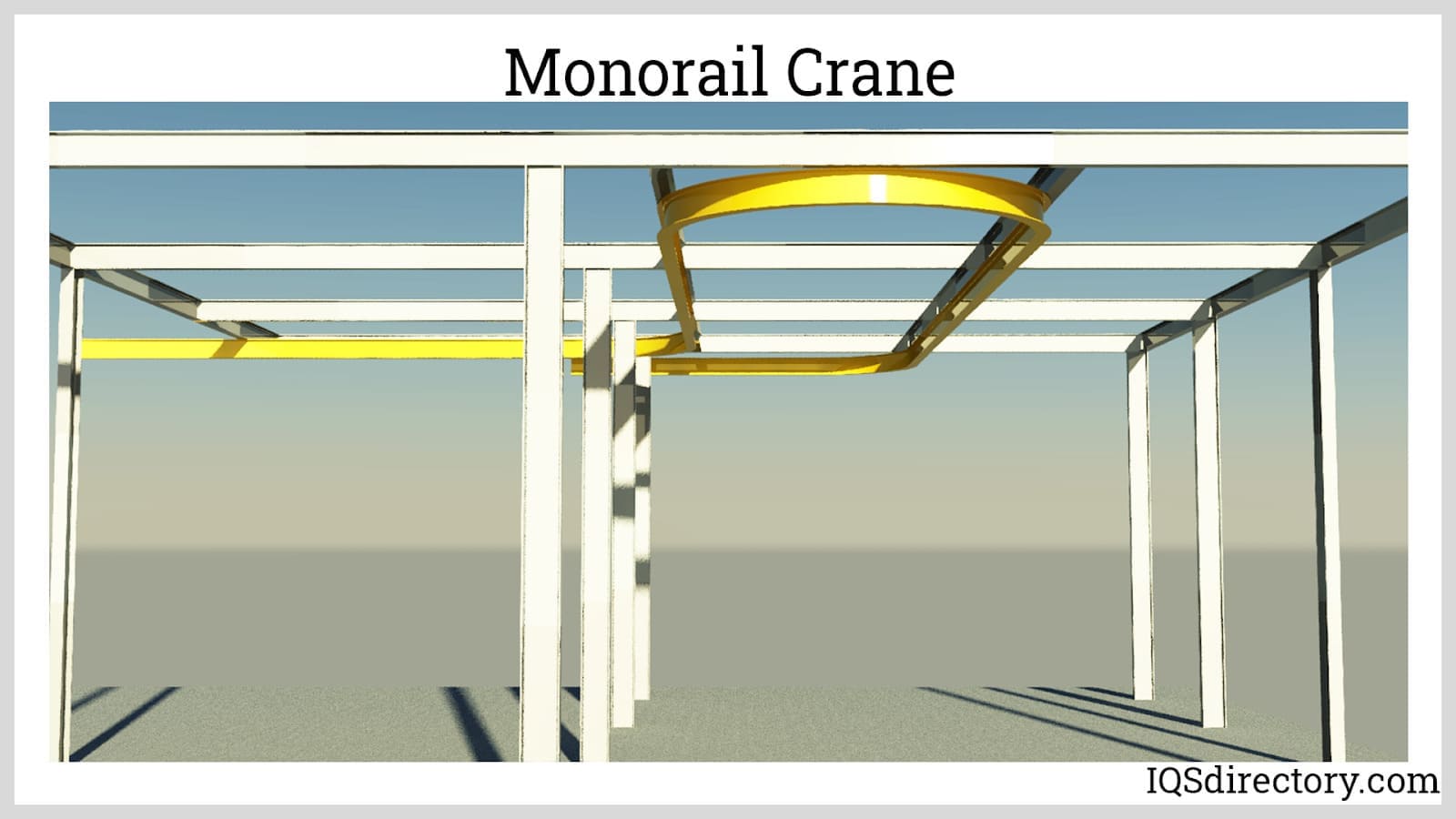

Monorail Cranes

Because it lacks a rafter, a monorail crane is unique from the others. A trolley attached to an I-beam that moves the hoist is part of the crane. The tracks of a typical monorail crane can be modified to fit the application, but the weight must travel in a straight path.

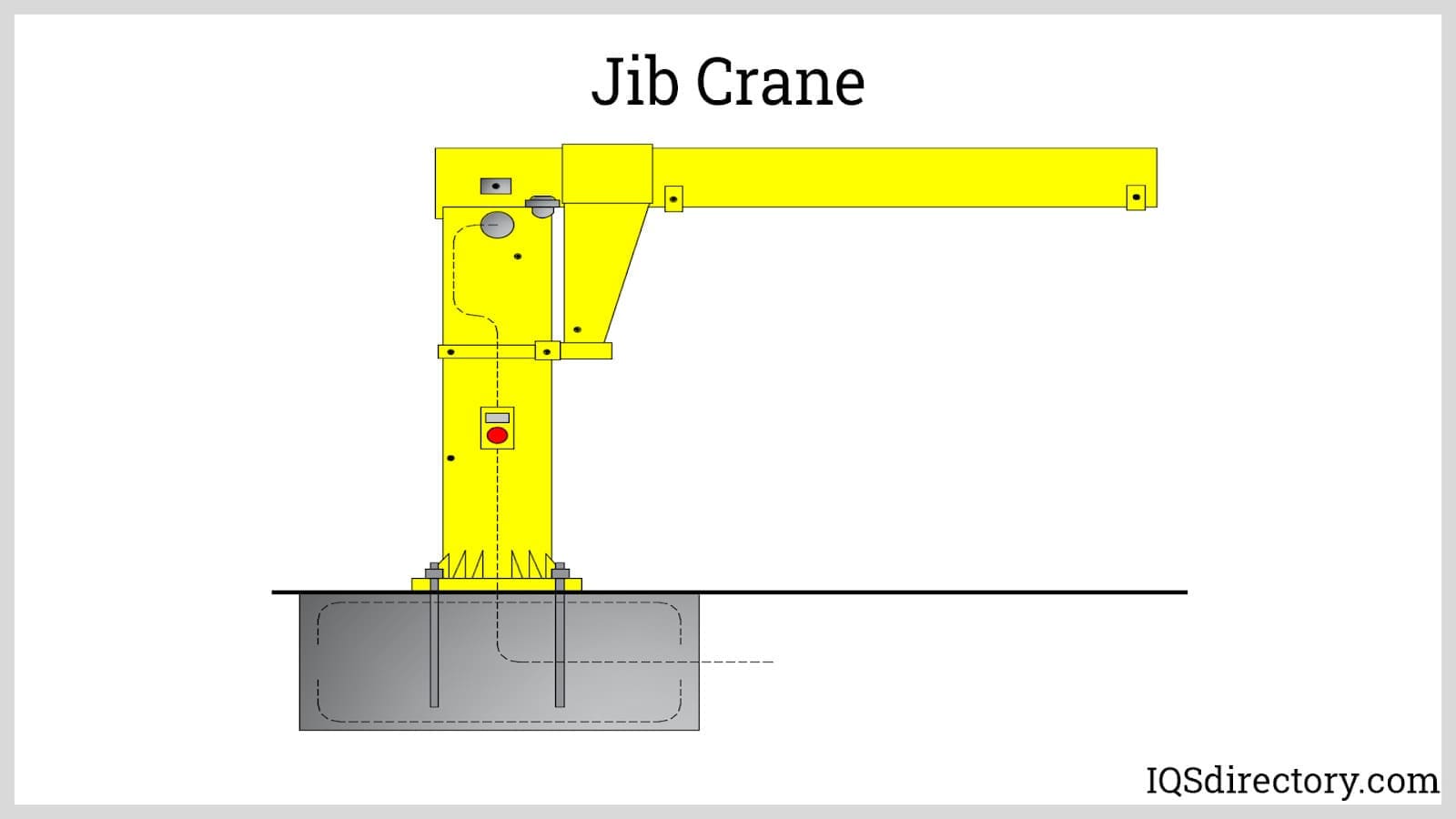

Jib Cranes

A jib crane hangs on a wall with a boom that extends over the coverage area; it lacks a runway system. Additionally, these overhead cranes may stand alone.

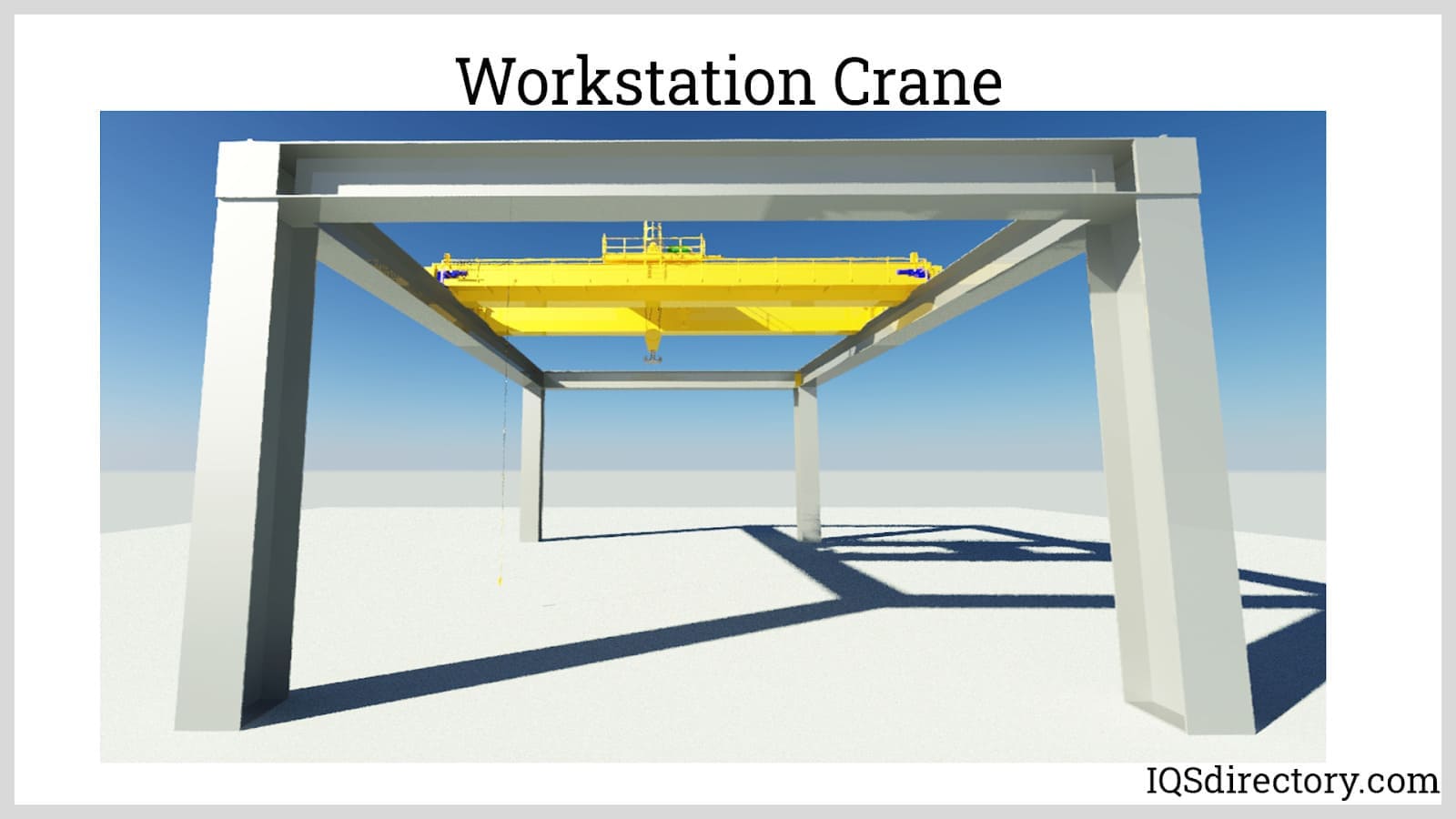

Workstation Cranes

Constructed for usage in regions with limited space, workstation cranes are lightweight. It has a straightforward design and has a lifting capacity of up to two tonnes of material.

Construction of an Overhead Crane

- Beyond what has to be lifted or the items being loaded, several more considerations exist in designing and selecting an overhead crane.

- It is crucial to fully comprehend how the overhead crane will fit into the operation because these cranes are made, formed, structured, and manufactured to match certain situations.

- No matter how a crane is configured, all overhead cranes require the same three fundamental building blocks: a bridge, a trolley, and a hoist.

- In bridge and gantry cranes, the bridge spans two supports; however, in jib cranes and cantilever cranes, bridges are carried in the air from one support; in these circumstances, the load carrying arm is sometimes referred to as a boom.

Working of an Overhead Crane

- Overhead cranes are powered by hydraulics, internal combustion engines, or electric batteries.

- The hoist and crane hook are moved along the bridge by a mechanical or electrically-driven system known as the trolley.

- The device that lowers and raises the crane attachment, hook, grapple, fork, or auger is called a hoist.

- The main electric, internal combustion, or hydraulic lift of the crane, located at the bottom or top of its support, is connected to the crane attachment by a wire rope or nylon cables. Electric motors are used for smaller applications, while internal combustion or hydraulic power is used for larger, heavier work.

Benefits of Overhead Cranes

- Quickly transferring bulky objects from storage to the shipping port is a key advantage of an overhead crane in warehousing.

- They lessen the potential of material or product damage.

- Overhead cranes reduce expenses and improve workflow.

- These cranes reduce environmental impact via a green solution.

Applications of Overhead Cranes

- The first industry to come to mind while considering the need for an overhead crane is warehousing since equipment, supplies, and materials are constantly being moved, set up, and prepared.

- Overhead cranes are frequently employed in refining steel and other metals like copper and aluminum. Metal is handled by an overhead crane throughout the production process until it exits the plant as a finished product.

- Large-equipment assembly firms employ overhead cranes because they need a way to lift and move unfinished assemblies from one place to another so they may be finished.

- When big, bulky items need to be placed into cars, trains, or trucks for transportation, the same rules apply to storage. Large goods may be arranged for shipment with ease using overhead cranes.

- By gently moving and arranging items for easier access, overhead cranes help to facilitate repairs of punch presses and other production equipment.

Choosing the Correct Overhead Cranes Company

To make sure you have the most positive outcome when purchasing Overhead Cranes from an Overhead Cranes Supplier, it is important to compare at least 5 or 6 Companies using our list of Overhead Cranes suppliers. Each Overhead Cranes Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Overhead Cranes business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Overhead Cranes businesses with the same quote.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches